Display is a device used to present visual information. The main aim of any display technology is to simplify the information sharing. Today, there are different types of displays used for different applications. These displays can be categorized as Video Displays, Non- Video Displays and 3D displays.

Video Displays are two-dimensional displays that cover a full area, basically a rectangle. The different types of video displays are discussed below

Electroluminescent Display

Electroluminescent display is a flat panel display that works on the principle of electroluminescence. Electroluminescence is a phenomenon where materials can emit light in response to the electric current. To make use of this phenomenon, electroluminescent display uses gallium arsenide (GaAs) as an electroluminescent material. The basic structure of electroluminescent display consists of electrode layers at the top and bottom. Active Matrix, Thin Film and Thick Dielectric are the three types of electroluminescent displays.

Advantages

Thin and compact.

Good writing speed.

Low voltage operation.

Disadvantages

Low efficiency.

High cost.

High voltage drivers.

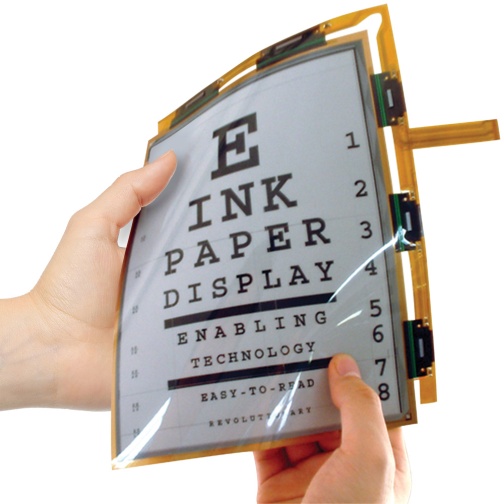

Electronic Paper

Electronic Paper also known as e-paper is a term for display technologies resembling a paper. The popularity of the display is due to its contrast, thickness, readability and flexibility.

E Ink is now one of the popular e-paper display technologies. It was developed by E Ink Corporation and today they are used by different companies in their products and e-readers. E Ink displays are made of some tiny capsules which consist of black and white particles. With the help of electricity either the black or white particles rise up towards the capsule and thereby change the color of the pixel. In order to make an e-ink display, first the ink is printed to a sheet made of plastic which acts as the front plane of the e-ink display. The plastic sheets are thereafter laminated onto the active matrix backplanes forming the e-ink display. To control the pattern of the pixels in the display, controllers and integrated circuits are added.

Advantages

Less power.

Easy to read at outdoors.

Disadvantages

Can’t display full videos.

Cannot be read in dark.

Gyricon is a type of e-paper display. It was developed by Xerox PARC. The main features of the display are its flexibility, wide angle of view etc. Gyricon sheet is a transparent plastic which consists of many beads that are distributed randomly. When the voltage is applied, beads will rotate to present the colored side to the viewer.

LED Display

It is a type of display that uses light emitting diodes.

LED is short for Light Emitting Diode. An LED emits light as a result of electric luminescence. It is also known as “cold light” as, unlike with old-fashioned incandescent bulbs, the light is not produced by heating a metal filament. The diode, on the other hand, emits light when flowing through two specially coated silicon semiconductors. It is one of the most energy-efficient and power-saving ways to produce light.

An LED consists of solid materials without movable parts and is often moulded into transparent plastic. This ensures high durability. When an LED is on, it emits almost zero heat. This reduces the problem of cooling the electronic parts.

The first LED was created by Russian inventor Oleg Losev in 1927. For many years, it was only possible to produce infrared, red and yellow LEDs. These diodes were found in everything from remote controls to clock radios.

It was not until 1994 that Japanese scientist Shuji Nakamura was able to demonstrate an efficient blue LED. White and green LEDs soon followed, laying the foundation for the LED revolution we have seen in lighting and display technology.

An LED display consists of many closely-spaced LEDs. By varying the brightness of each LED, the diodes jointly form an image on the display.

An LED display consists of many closely-spaced LEDs. By varying the brightness of each LED, the diodes jointly form an image on the display.

To create a bright colour image, the principles of additive colour mixing are used, whereby new colours are created by mixing light in different colours. An LED display consists of red, green and blue LEDs mounted in a fixed pattern. These three colours combine to form a pixel. By adjusting the intensity of the diodes, billions of colours can be formed. When you look at the LED screen from a certain distance, the array of coloured pixels are seen as an image.

ADVANTAGES:

Long Service Life

Good environmental performance

Low heat generation

Low Power

Many Color Choices

DISADVANTAGES:

Sensitive to Voltage Spike

Heat dissipation in some applications

Not true full spectrum White LED (unless tri-color)

This flat panel display is today used in many applications like to display traffic signs, displays of railway stations, television display etc. One of the largest LED display in the world is located in China, which is 500m long. Also the largest LED television is the Center Hung Video Display at Cowboys Stadium. This television has dimensions of 49m x 22m.

Liquid Crystal Display(LCD)

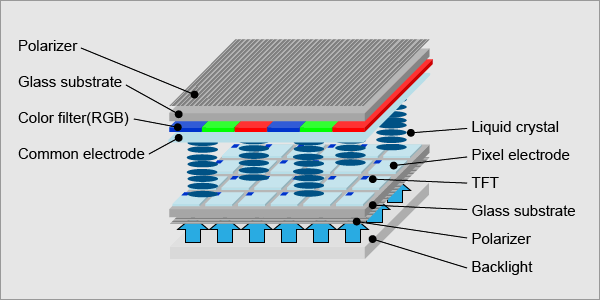

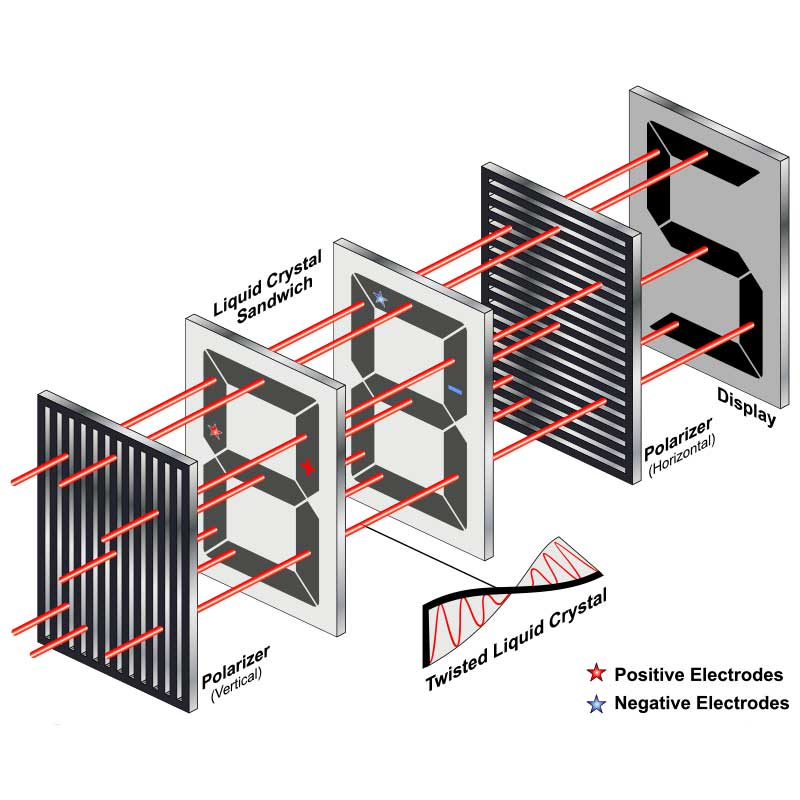

This display generally depends upon the light modulating properties of liquid crystals. The low power consumption makes it good to use in all types of electronic equipments that are battery powered. LCDs are electronically modulated and are made of liquid crystals which are arrayed in front of the light source to produce images in color.

LCDs are commonly used in systems, such as calculators and laptop computers. These non-emissive devices produce a picture by passing polarized light from the surrounding or from an internal light source through a liquid- crystal material that can be aligned to either block or transmit the light. A liquid crystal display consists of an array of tiny segments (called pixels) that can be manipulated to present information. The main advantage of LCD is size. There is no huge picture tube. The drawbacks with LCDs are viewing angle, contrast ratio, and response time.

TFT LCD Display

TFT LCD displays are another type of LCD display that uses the thin film transistor technology. This display helps to improve the quality of the image, contrast, addressability. Generally, TFT LCD is an active matrix LCD display.

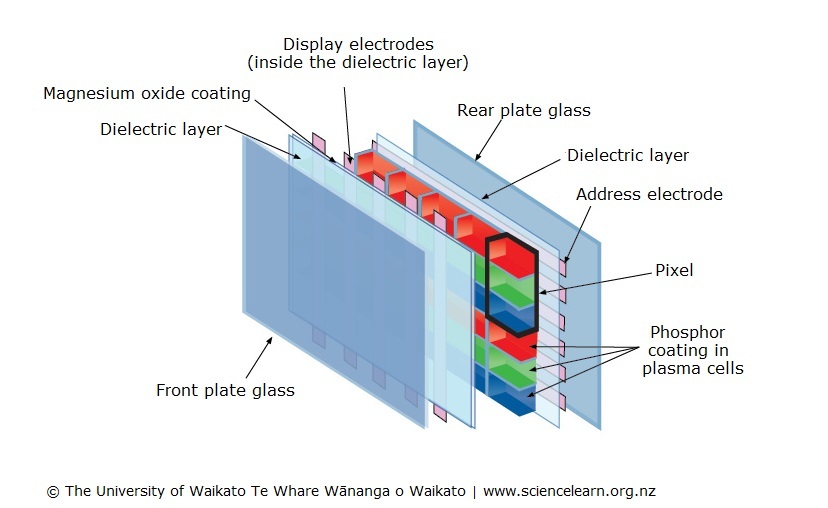

Plasma Display

Plasma panels, also called gas discharge displays, are constructed by filling the region between two glass plates with a mixture of gases that usually include neon. A series of vertical conducting ribbons is placed on one glass panel, and a set of horizontal ribbons is built into the other glass panel. Firing voltages applied to a pair of horizontal and vertical conductors cause the gas at the intersection of the two conductors to break down into a glowing plasma of electrons and ions. Picture definition is stored in a refresh buffer, and the firing voltages are applied to refresh the pixel positions (at the intersections of the conductors) 60 times per second.

Plasma Displays is one of the display technologies that provides large screen sizes and better flat screen presentation. Good image qualities are one of its characteristic. Basically, plasma screens compose of large number of cells sandwiched between the panels made of glass. Between the glass panels there are display and address electrodes which form the grid. Electrodes intersect at a particular cell will get charged and excites neon and xenon gas within each cell. When the gas gets excited, it creates plasma and releases the UV light and thereafter releases the phosphor electrodes which are located on the sides of the cell. When these electrodes come back to the original state, light is emitted.

Plasma panel displays text or graphics using the light from large number of tiny plasma cells. Each pixel is made up of three sub cells which emit red, green and blue lights for colour display. Plasma display is thinner than its CRT counter parts and wider display panels can be created using plasma technology.

Plasma is an ionized gas containing free-flowing ions and electrons. Under normal condition, gas inside the chamber is neutral. Plasma is created by applying very high voltage across the electrodes on the sides of the gas chamber. Structure of a single plasma cell is shown in the figure.

When a voltage is applied between two electrodes, free electrons are introduced into the gas. These free electrons collide with the electrons in the gas atoms. Electrons will get enough energy to break its bond, therefore, more free electrons and positive ions are created. Electrons then move towards the positive charged area and similarly positive ions move towards the negatively charged area.

Random movements of charged particles increase the rate of collision and therefore, more and more charged particles get released. Each exited electrons after some time go back to the lower energy state by emitting energy in the form of photons.

Xenon and Neon are most commonly used gases to make plasma. When they are excited, photons are created in UV range. Ultraviolet rays are invisible to human eye and therefore they need to be converted into visible spectrum. For which ultraviolet photons are guided to hit a phosphorus layer on the surface of the gas chamber. Incident ultraviolet rays excite phosphorus electrons to a higher energy state. The electron later returns to the ground state and releases energy in the form of photon in visible spectrum.

Construction of Plasma Display

A large number of tiny plasma cells are arranged in a matrix format. Each cell is addressed by grid structure (rows and columns) of long electrodes which reaches both sides of the cell. When voltage pulse is applied across any two electrodes, gas cell at the intersection electrodes are excited.

Ultraviolet photons in each cell interact with phosphor material coated on the inside wall of the cell to emit photons in the visible spectrum. In a small fraction of a second, thousands of such cells are excited to display a particular graphics on the screen. Since each pixel lights individually, no separate back light is required for plasma display.

Colour Display

In colour display every pixel is made up of three separate sub pixels. Each sub pixels is coated with three different phosphors to emit red, green and blue lights. Colours from each sub pixel blend together to create the overall colour of the pixel.

OLED DISPLAY

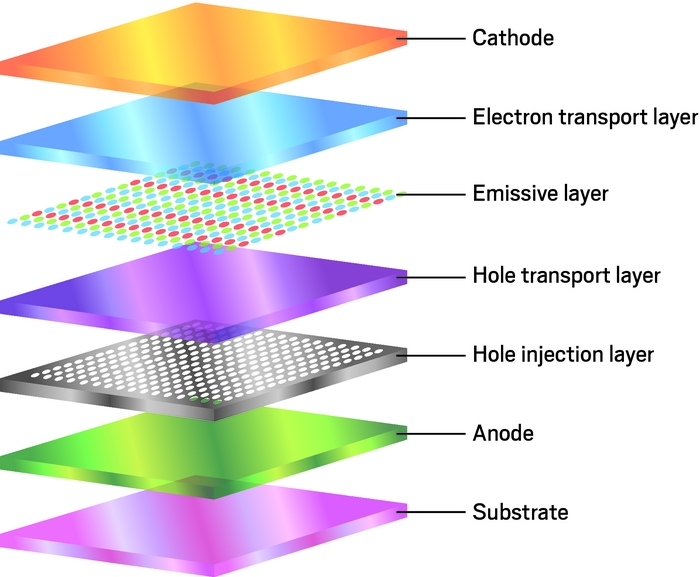

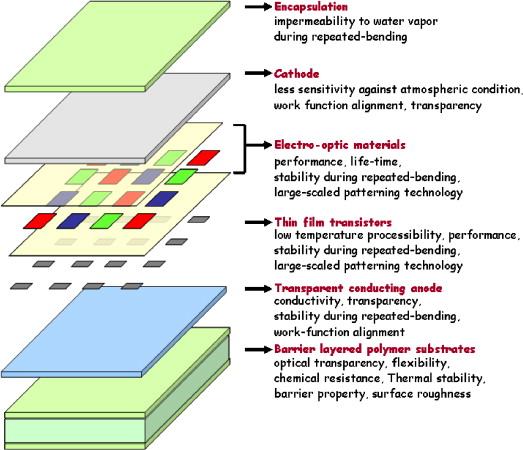

OLED means Organic Light Emitting Diode. As the name indicates that it relies on organic materials. Organic Light Emitting Devices (OLED) emit light from active luminescent material in each display pixel.

OLED panels are made from organic materials that emit light when electricity is applied through them. Since OLEDs do not require a backlight and filters (like LCD displays do), they are more efficient, simpler to make, and much thinner - and in fact can be made flexible and even rollable.

The main component in an OLED display is the OLED emitter - an organic (carbon-based) material that emits light when electricity is applied. The basic structure of an OLED is an emissive layer sandwiched between a cathode (which injects electrons) and an anode (which removes electrons).

There are various type of OLED like PHOLED (phosphorescent OLED), TOLED (Transparent OLED), FOLED (Flexible OLED), WOLED (White OLED), AMOLED (Active matrix OLED). OLED’s basic structure consists of organic materials positioned between the cathode and the anode, which is composed of electric conductive transparent Indium Tin Oxide (ITO).

Modern OLED devices use many more layers in order to make them more efficient and durable, but the basic functionality remains the same.

An OLED panel itself is made from a substrate, backplane (electronics - the driver), frontplane (the organic materials and electrodes as explained above) and an encapsulation layer. OLEDs are very sensitive to oxygen and moisture and so the encapsulation layer is critical.

The substrate and backplane of an OLED display are similar to those of an LCD display, but the front plane deposition is unique to OLEDs. There are several ways to deposit and pattern the organic layers. Currently most OLED displays are made using vacuum evaporation, using a Shadow Mask (FMM, Fine Metal Mask) to pattern. This is a relatively simple method but it is inefficient (a lot of material is wasted) and very difficult to scale up to large substrates.

Some OLED materials are soluble, and these can be deposited using printing methods - mostly ink-jet printing. OLED makers hope that ink-jet printing may be a scalable, efficient and cheap way to deposit OLEDs.

The organic materials compose a multi-layered thin film, which includes the Hole Transporting Layer (HTL), Emission Layer (EML) and the Electron Transporting Layer (ETL). By applying the appropriate electric voltage, holes and electrons are injected into the EML from the anode and the cathode, respectively. The holes and electrons combine inside the EML to form excitons, after which electroluminescence occurs. The transfer material, emission layer material and choice of electrode are the key factors that determine the quality of OLED components.

ADVANTAGES

Vibrant color

High Contrast

High Viewing angle

Rapid Response Time

Full motion videos

Low Cost

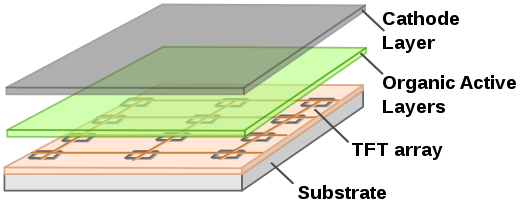

AMOLED DISPLAY

The full form of AMOLED is Active Matrix OLED. It has better display quality, thin form factor, and lower power consumption. In this display technology a very thin film has been used which was coated with several organic electroluminescent compounds. The whole technology is too dealt with the pixel quality of the displays. As of now this display technology has been implanted very successfully in small screens like in smart phones. This technology is not only very affordable, but also available with improved quality picture. In very near future AMOLED will be used for bigger screens.

The active matrix OLED in AMOLED technology produces a light after it is properly electrically activated. It requires a continuous flow of electricity and that is controlled by two TFTs. The benefit of this technology over others is immense. AMOLED technology consumes lesser power and also the refresh rate is very high than other counterparts. The response time of touch displays developed using this technology is far better compared to others. In future it is going to be used not only in portable electronics devices, but also in large screens such as more than 50 inches. Already several big names in the electronics world have started using an AMOLED including Samsung.

ADVANTAGE

Wide Temperature operation

Fast Response

High and constant Gamut color

Wide viewing angle

Peak brightness

Low power consumption

Very slim design

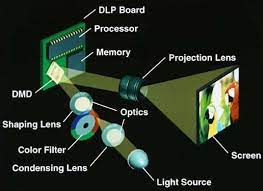

Digital Light Processing Technology

DLP technology basically uses an optical semiconductor device known as Digital Micromirror Device. This device is a small light switch that can modulate the light through many microscopic mirrors arranged in a rectangular array. By using a DMD, digital video, light source, projection lens and mirrors this DLP system can reflect a digital image to the surface. When the mirrors tilt towards the light source, they are in the ON state otherwise they are OFF. Depending upon the state of the micromirrors, they project light or dark pixels to the screen. A digital signal is used to instruct the micromirror to switch on or off. With the help of this method, the DMD can produce grayscale images.

In order to produce color images, a color wheel is placed between the mirror and the light source. When the wheel spins, white light generated will filter into red, green and blue light which then fall onto the mirrors. The coordination of the colored light and switching of the DMD, the DLP system helps to produce colored images. For example, a purple pixel will be produced when the mirror is switched ON when red or blue colored light is produced.

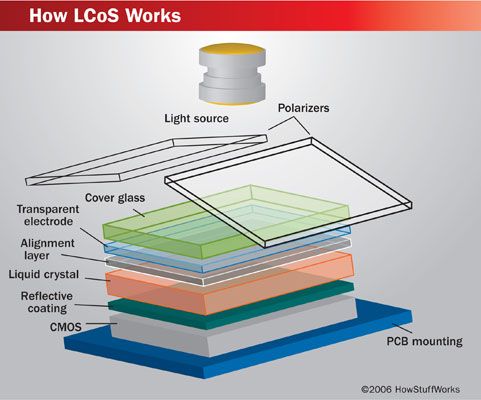

Liquid on Silicon (LCoS)

Liquid crystal on silicon (LCOS) is a reflective microdisplay technology that is based on a silicon backplate. It is a combination of digital light processing (DLP) and liquid crystal display (LCD) projection technologies as it is reflective, but instead of using mirrors as in DLP, it uses liquid crystals that are applied on a reflective silicon backplate. Light is reflected off the backplate, while the liquid crystals open and close to modulate it.

LCOS microdisplay is constructed with a liquid crystal layer sandwiched between a thin-film transistor (TFT) and a silicon semiconductor with a reflective coating, hence the name. Like in DLP technology, light passing through a polarizing layer is reflected, but in the case of LCOS, it uses a reflective semiconductor instead of mirrors, while the liquid crystals act as gates that control the amount of light that passes and reaches the reflective surface, modulating the light and creating the image. As with LCD technology, LCOS modulates light in the RGB channel, so there are still three separate subpixels of red, green and blue.

Parts of an LCOS microdisplay starting from the top:

Glass cover -- Seals and protects the system.

Transparent electrode -- Completes the circuit with the liquid crystal and the silicon.

Alignment layer -- Aligns the liquid crystal in order for them to accurately direct light.

Liquid crystal -- Controls the amount of light that reaches and leaves the reflective layer.

Reflective coating/layer -- Reflects light that creates the picture.

Silicon or chip -- Controls the liquid crystal in a one-to-one ratio between pixel and transistor using data from the display driver.

Printed circuit board -- Carries instructions from the television or computer into the devices.

LCOS offers the following advantages:

High brightness while maintaining a contrast ratio of 2,000:1

High light efficiency as 70-80% of light is reflected

High-quality image as there is no "screen door" between pixels

High heat efficiency

Field Emission Display

This is another popular flat panel display technology. It uses filed emission electron sources. These electron sources will strike the phosphor to produce colored images. Generally, FED consists of CRTs to form the RGB pixels. High contrast ratio, fast response time, less power, better packaging are some of its features.

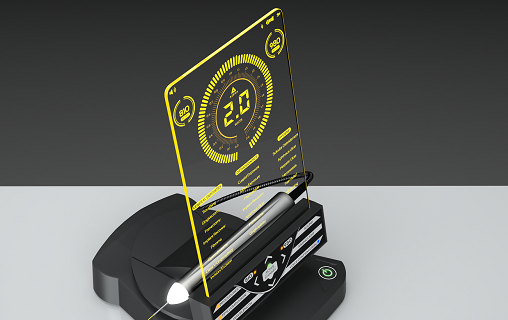

Laser TV

Laser color television (laser TV), or laser color video display utilizes two or more individually modulated optical (laser) rays of different colors to produce a combined spot that is scanned and projected across the image plane by a polygon-mirror system or less effectively by optoelectronic means to produce a color-television display.

Thus, Laser TV also known as Laser color video display uses laser rays of different colors in order to produce a spot. The spot is scanned and projected across the image plane. This process is done by using a polygon mirror set up.

The systems work either by scanning the entire picture a dot at a time and modulating the laser directly at high frequency, much like the electron beams in a cathode ray tube, or by optically spreading and then modulating the laser and scanning a line at a time, the line itself being modulated in much the same way as with digital light processing (DLP).

Laser TV technology began to appear in the 1990s. In the 21st century, the rapid development and maturity of semiconductor lasers and other technologies gave it new advantages.

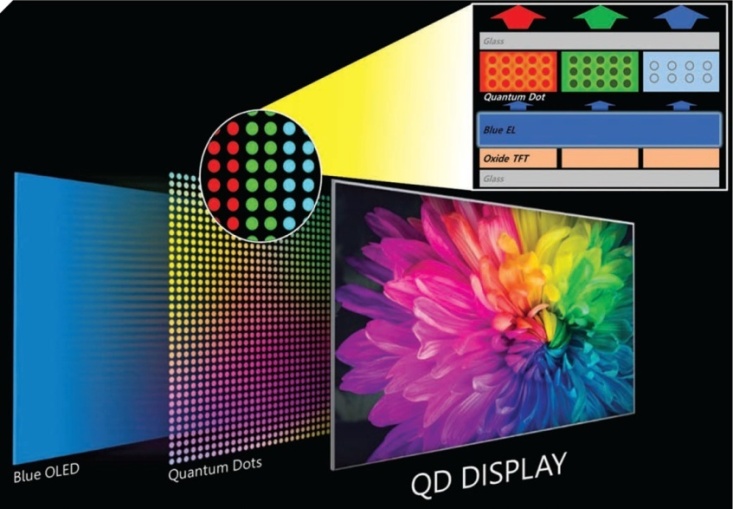

Quantum Dot Display

Quantum dot display is a type of display technology similar to the OLEDs. Here the light is supplied earlier, so that more efficient displays are obtained. Quantum dots are considered to be electro-active and photo-active which makes them to be a better display technology.

A quantum dot display is a display device that uses quantum dots (QD), semiconductor nanocrystals which can produce pure monochromatic[a] red, green, and blue light.

Photo-emissive quantum dot particles are used in LCD backlights and/or display color filters. Quantum dots are excited by the blue light from the display panel to emit pure basic colors, which reduces light losses and color crosstalk in color filters, improving display brightness and color gamut. Light travels through QD filters with red/green QD color converters and blue pass through. Although the QD color filter technology is primarily used in LED-backlit LCDs, it is applicable to other display technologies which use color filters, such as blue/UV AMOLED/QNED/MicroLED display panels.

LED-backlit LCDs are the main application of photo-emissive quantum dots, though blue OLED panels with QD color filters are being researched.

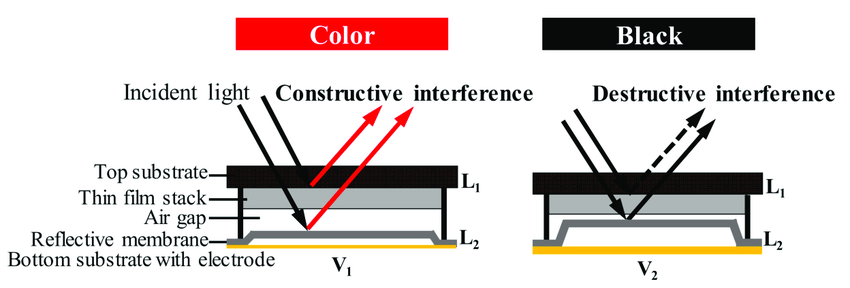

Interferometric Modulator Display

IMOD displays are a particular type of electronic visual displays that helps to create different colors by the interference property of the reflected light. One of the smart watches named Qualcomm Toq uses this type of display. IMOD displays consist of mirrors that can be made into ON or OFF states. Each of these mirrors will reflect only one wavelength of light when turned ON. When the mirrors are in the OFF state, they absorb the light. Generally the mirrors here are arranged in a rectangular array to make up a display screen.

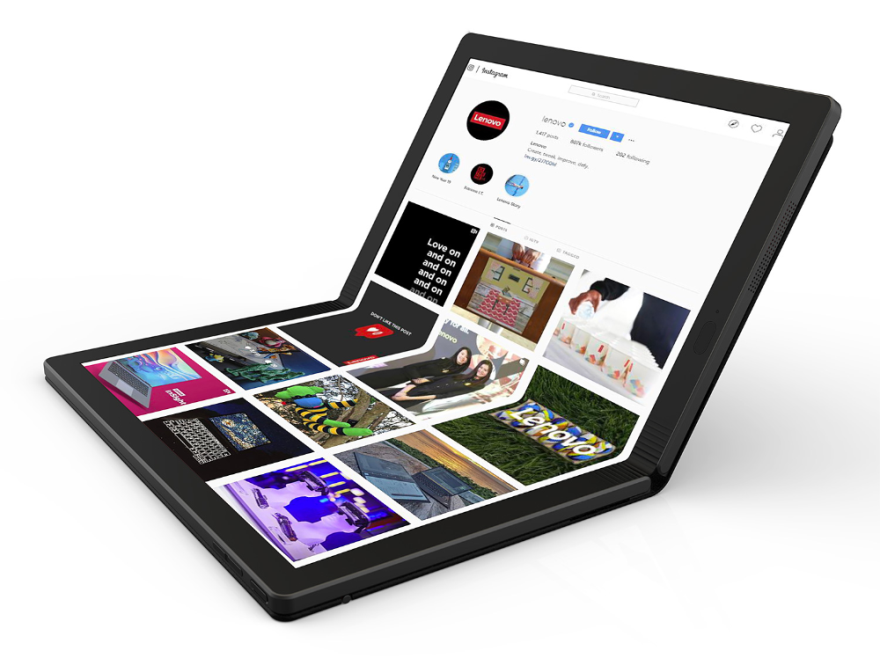

A flexible display is referred to the display of the screen which is actually quite flexible by nature. These sorts of screen are quite different from the usual rigid flat screens that can be explored in the world of electronics today. With the increase in the popularity of these types of screens, many manufactures have intended to include this style of display in mobile phones, e-readers and many more electronical devices that have flat screen. The concept of this technology is derived from the age old flexible electronic paper.

A flexible electronic paper is a paper that is often termed as the e-paper and this paper has the ability to bend and is even structured as the prototype of the current technology. Though, there were several companies who tried formulating this concept with the help of smart skills and competence, but only in the year 2013 the world could discover the first and the most beautiful screen which is flexible and easy to use. This concept was first identified by the Xerox PARC (Palo Alto Research Company) in the year 1947. Scientists like Nicholas K. Sheldon had made major contribution in the development of this screen.

Dubbed Gryicon was the technology that could make flexible display what it is today. This new display technique was designed using e-paper and the dynamic touch of the digital display. Soon, this idea was well structured with the help of Organic thin film transistors. These organic thin film transistors acted as a semiconducting compound that provided adequate amount of mobility to the display. The worked in bringing a brighter and vibrant display on the screen and even increased the response time of the screen.

The Organic semiconductors typically hold low intermolecular force, which means the Vander Waal Force of attraction between them is as low as 10kcal/mol. This means that the bonding that is present between the atoms of the organic thin film transistors are quite low, even lower than the inorganic compounds like Silicon, Gallium, and Germanium that hold quite a strong bonding in between them. So, the low bond value that was present in between the organic compounds, especially in the thin film transistors allowed the display screen to bend without breaking. Since, the intermolecular force is not too strong any type of damage was never caused to the screen.

Every Rollable display is a type of flexible display, but on the contrary every flexible display is not a type of Rollable display. This clearly, means that any display that is flexible does not mean that it can be rolled over too. As a matter of fact, there are only few such display that are flexible and Rollable too. The common Rollable display is almost like a thin piece of paper that can be rolled into any direction, and was developed with the help of E-paper that had E-ink. Currently, there is only one phone by Samsung which is named as Youm, and this phone holds both flexible and Rollable display too.

The phone was enthralled by Samsung in the year 2013, and was crafted as an unnamed product. This was the time, when the brand engineers announced their developments for creating display screen that is both flexible and Rollable but, it can be purchased by everyone at affordable rates. After that, Samsung brought an official name that was Youm to the first curved OLED screen phone that was Rollable and flexible too. This OLED display enhanced the battery life of the phone and soon made the phone a new revolution in the world of Smartphone.

Advantages of Flexible and Rollable Display

Disadvantages of Flexible and Rollable Display

Future Developments of Flexible and Rollable Display

For now, there has been lot of talk in the air about flexible display and the features that they hold. This has definitely increased the anticipation of the people and now they are waiting when they will be able to use such kind of phone, which is based on the smart technology of today. It’s interesting that Samsung has brought a phone that can achieve the same standards of that of OLED with display that is flexible, but it has not yet announced the launch date of this phone.

IPS DISPLAY

The full form IPS is In-Plane Switching. It is a technology that addresses the two main issues of a standard twisted nematic (TN) TFT display: color and viewing angle. With IPS, the crystals are aligned horizontally to the screen rather than vertically, and the electrical field is applied between each end of the crystal molecules –termed a lateral electric field. In this way, the crystals are kept parallel to the electrode pair, and thus the glass substrate of the screen. The liquid crystal molecules are not anchored to the lower glass substrate, so move more freely into the desired alignment.

Curved screens theoretically provide a larger field of view and a more “immersive” experience.

© 2025 iasgyan. All right reserved