Introduction

Plastics and plastic packaging are everywhere around us, with a disastrous impact on the planet. In response, there has been growing interest in recent years for developing new types of biodegradable plastics.

In 1974, certain polymers were shown to degrade quickly in soils with many microorganisms. In the past 20 years, researchers have been looking into more eco-friendly plastic solutions.

Let’s look more closely at the concept of biodegradability.

“A product is biodegradable when it can be decomposed by biological organisms (bacteria, fungi, algae, etc.) in a favourable environment (temperature, humidity, light, oxygen, etc.)”— Futura Science. Biodegradation can be “anaerobic” (without oxygen) or “aerobic” (in the presence of oxygen).

More specifically, biodegradation has two key steps:

Biodegradable plastics

Biodegradable plastics are those that can decompose naturally in the environment. The makeup structure of biodegradable plastics makes them easily break down by natural microorganisms, giving an end product that is less harmful to the environment.

Biodegradable plastics are perceived to be more eco-friendly due to their environmental benefits, which are hard to deny compared to ordinary plastics.

To minimize environmental pollution, this type of plastic is undoubtedly a better choice but still comes with its downside. Here, we look at how biodegradable plastics are made, their benefits and problems, and examples of their uses.

The history of bioplastics started a long time ago. One of the very first man-made bioplastics, called Parkesine, was created in 1862 by Alexander Parkes (UK) from cellulose.

Another early known bioplastic (made from bacteria) was discovered in 1926 by a French researcher, Maurice Lemoigne.

How are Biodegradable Plastics Made?

Biodegradable plastics are made in a way that they can breakdown or degrade when exposed to the sun’s ultra-violet radiation, enzymes, bacteria, water, or wind abrasion.

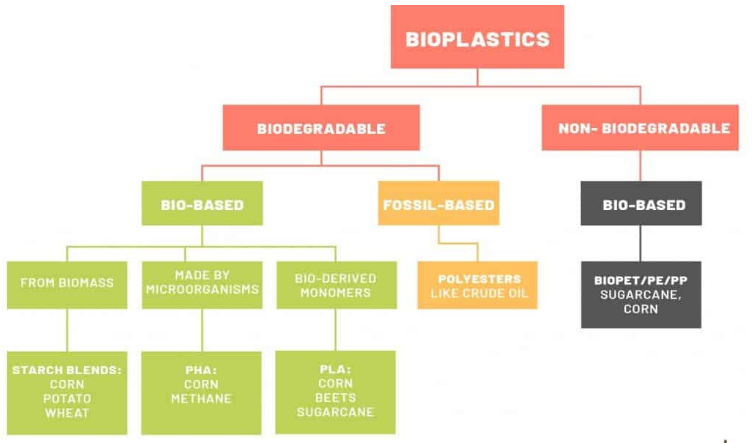

Biodegradable plastics can be made from 1) a mixture of organic bio-based materials, such as starch and cellulose; 2) biodegradable synthetic polyesters that are fossil-based or 3) bio-based oils, such as sugarcane, which are not always biodegradable.

Thus, they are made from renewable raw materials or all-natural plant or animal materials such as orange peels, corn oil, switchgrass, soybeans, micro-organisms, or starch.

The industrial processing of biodegradable plastics is similar to the manufacture of ordinary plastic, only that the materials used differ and for bio-degradable plastics; they are the materials that can easily break down or decompose. They are mainly categorized into two:

The most common examples include polybutyrate adipate terephthalate (PBAT), polybutylene succinate (PBS), polyvinyl alcohol (PVOH/PVA), and polycaprolactone (PCL).

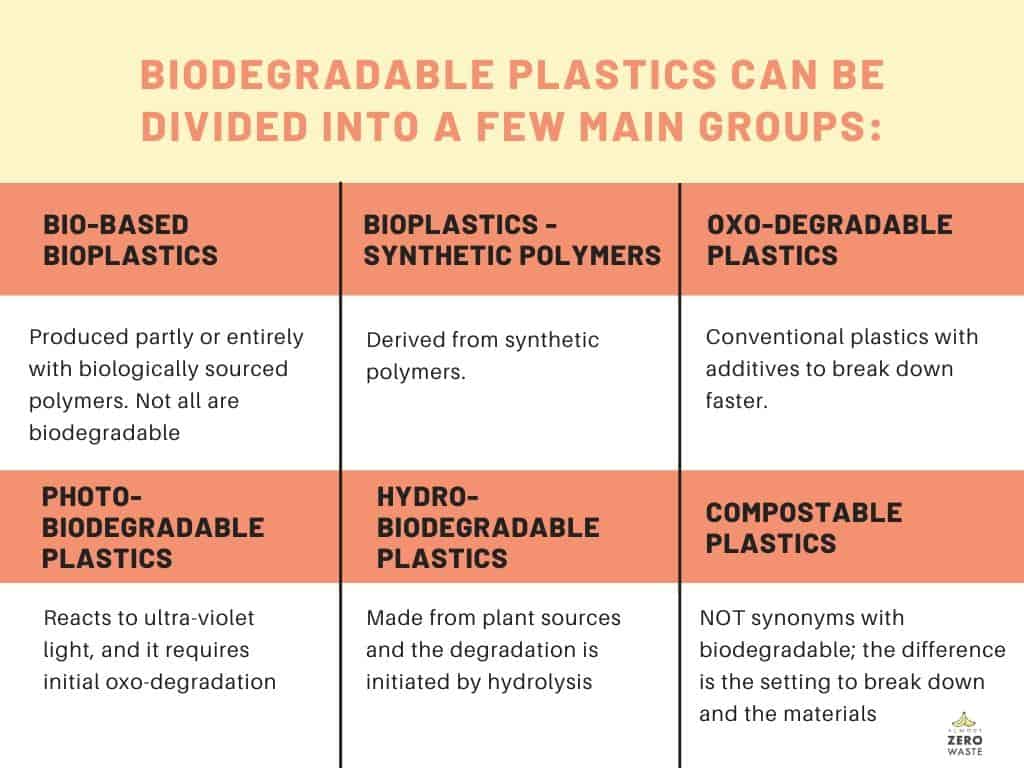

The types of biodegradable plastics are:

Bioplastics – produced partly or entirely with biologically sourced polymers. They can be derived from plants or in combination with synthetic polymers. Not all are biodegradable.

Oxo-degradable plastics – conventional plastics with additives to break down faster.

Photo-biodegradable – reacts to ultra-violet light, and it requires initial oxo-degradation.

Hydro-biodegradable plastics – made from plant sources (like starch) and the degradation is initiated by hydrolysis.

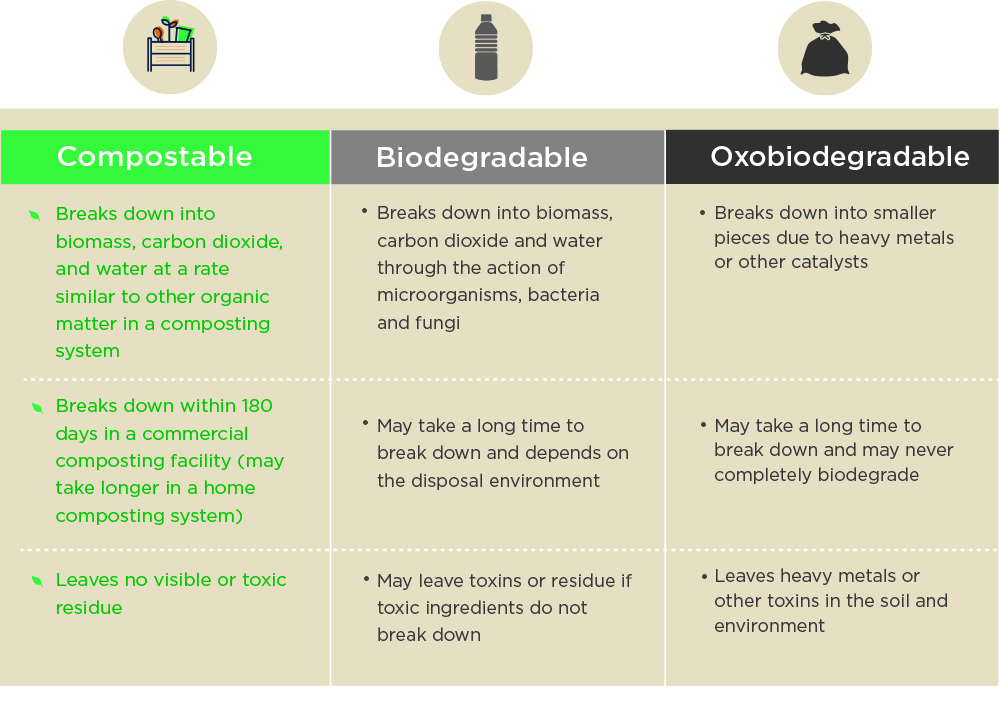

Industrially compostable plastics are designed to biodegrade in the conditions of an industrial composting plant or an industrial anaerobic digestion plant with a subsequent composting step.

Home compostable plastics are designed to biodegrade in the conditions of a well-managed home composter at lower temperatures than in industrial composting plants. Most of them also biodegrade in industrial composting plants.

Is bioplastic necessarily biodegradable?

No. A material’s biodegradation is determined by its chemical composition, not whether plant- or fossil-based. It is therefore important to differentiate between biosourced (the polymer is made of biomass) and biodegradable. A petroleum-sourced plastic can be biodegradable while a polymer can be biosourced but not biodegradable.

In summary, a bioplastic can be only biosourced, or only biodegradable. And it can sometimes be both! This is true for polylactic acid (PLA), which is part of the family of biosourced and biodegradable bioplastics. It is made from renewable resources such as corn or sugar cane.

Advantages of Using Biodegradable Plastics

These types of plastics not only take less time to decompose when discarded but can also be easily recycled through an organic process. They are also non-toxic since they have no chemicals or toxins. Recycling helps to lessen landfill problems, and besides, the recycled bio-waste can be used as compost or as renewable energy for biogas.

It is true that the production of biodegradable plastics requires more investment, but finally, it is worth it. If the clean-up costs are taken into consideration, besides the harmful effects on the environment, biodegradable plastic products will definitely turn out to be a wiser choice.

Less energy is needed in the manufacturing of biodegradable plastics compared to ordinary plastics. For instance, the manufacture of corn-based polymer requires 65% less energy compared to a similar polymer made from petroleum. Manufacturing bioplastics also do not require the process of finding, accessing, and transportation of hydrocarbons.

This means fewer fuel fossils will be in use; hence, reduction of environmental pollution. Also, it produces 68% fewer greenhouse gases during its manufacture, posing a significant environmental benefit.

Biodegradable plastic breaks down only in a period of a few months, depending on the material used to make the bioplastic and the method of disposal. Other types of traditional plastic constitute 13 percent of the waste stream that is 32 million tons of trash annually, and only 9 percent of this type of plastic can be recycled.

Biodegradable plastics are a better choice as they are broken down easily, and can be absorbed by the soil or converted into compost. Moreover, even if a complete breakdown does not occur, it is easy to achieve a reduction in the amount of space required to dispose of the globe’s plastic waste.

Oil is a significant ingredient in the manufacturing of traditional plastics. Petroleum is known to have negative impacts on the environment, considering the amount of waste produced during refinement and also during the extraction of oil from the earth.

In the United States alone, 3% of petroleum so produced is used in the manufacturing of plastics. What we must remember is that, like other fossil fuels, petroleum is a non-renewable resource that ought to be conserved.

Biodegradable plastics use the idea of natural products; therefore, the use of bioplastic can profoundly reduce the amount of petroleum used and consequently lessen its environmental hazards.

Composting of bioplastic products can make the soil fertile, thereby enhancing soil fertility. The reason for this is because plastic is not made using artificial chemicals but from natural materials. The materials decay and improve the soil’s water and nutrient retention and help in the growth of healthier plants with no need for pesticides and chemical fertilizers.

We are at a juncture where we are producing the largest amount of waste that the history of human civilization has ever seen. And needless to say, it is plastic products that form a major chunk of it. The situation is such that even our drinking water sources, which constitute a mere 1% of earth’s total water resources, are getting contaminated at an alarming rate.

The production of plastics has increased significantly over the years. Scientists have approximated that by the year 2050, there could be more plastics in the ocean than fish. Drinking water will be contaminated with 80% of microplastic at that time.

With biodegradable plastics, such as those made from sugar and carbon dioxide by researchers from the University of Bath, the world foresees a future of plastics that can decompose and release only the amount of energy that was used to make it.

Since fossil fuels are not required in the manufacturing process of such nature-friendly, biodegradable plastic products, the carbon dioxide emissions are also curtailed. Their decomposition does not produce an excess of CO2, but only as much that had been used up in producing them.

The use of biodegradable plastic products instead of traditional plastics lessens the amount of greenhouse gas emissions.

A little statistical survey would reveal that we are using nearly 100 million tons of plastic every year. And the production of such staggering amounts of plastic products releases approximately 500 million tons of carbon dioxide into our atmosphere. If you are wondering how much carbon dioxide that is, it is the emission produced by 19 million vehicles annually.

Switching to bioplastics can profoundly reduce the number of greenhouse gasses emitted, consequently avoiding its effects such as desertification and extreme flooding.

Discarding traditional plastics can also mean releasing methane, toxic chemicals, and other types of pollutants to the environment. These substances, while breaking down, are potentially dangerous as they can easily harm marine and terrestrial ecosystems, and overall human health as well.

Bisphenol A – a significant component in the manufacturing of plastics, for instance, is associated with the endocrine disruption that is incredibly harmful to the reproduction cycle of human beings. Other artificial chemicals in traditional plastics have also been linked to diseases such as cancers.

Shifting to biodegradable plastic products means cutting down on the release of these lethal products into the environment and making way for a better, healthier future for the generations to come.

Biodegradable plastic products are a little closer to nature. Since their decomposition does not release harmful products, it becomes easier for us to manage them better. When buried in the soil, bacteria in the soil start decomposing it.

As a result, we are left with manageable amounts of waste. Not just that, since this decomposition process is natural, so the amount of fossil fuel or energy consumed in the process is nil, and thus, it is also cost-effective.

This is probably one of the best benefits of biodegradable plastic products. They are flexible. Once the desired biodegradable material is converted into a polymer, it can be easily combined with the traditional products that are used for making plastic traditionally. So, completely new products do not have to be manufactured to produce biodegradable plastic products.

Biodegradable plastic products are on the verge of becoming the booming industry of this generation. It will not only create ripples in the export industry but also in the marketing industry.

In 2016 alone, China produced and used 290,000 and 130,000 tons of biodegradable plastic products, and their local businesses saw a 13% hike in sales, which accounts for $350 million. With people becoming more aware and willing to reduce their carbon footprints, it goes without saying that biodegradable plastic products will be in high demand very soon.

Apart from that, many companies have targeted this aware section of people to increase their sales. The soft drinks giant Coca-Cola has started making bottles out of biodegradable plastics. Not only are they doing their bit for the environment, but also they are increasing their sales with their improved marketing strategies.

Among all the other good qualities, this is yet another feather in the cap of the biodegradable plastic products. Not only is their decomposition relatively easier and less harmful, but these products can also be decomposed under specific conditions.

We must not forget that corn-starch is an important product used in the manufacture of these plastics. When this corn starch comes in contact with water, it can breakdown within a matter of weeks without any hassle.

Disadvantages of Biodegradable Plastics

Biodegradable plastics are made from plants such as soybeans and corn. Therefore, there is a risk of contamination as the crops are typically sprayed with pesticides when on the farm and can easily be transferred or included in the end product.

A downside of biodegradable plastic is that there is a need for costly industrial processors and composters, especially those that require high industrial-scale temperatures to be broken down. Apart from cost, there is a need for the availability of equipment, which may be a problem.

These bioplastics should not be mixed with non-biodegradable plastic when discarded. The challenge today is that many people do not know how to distinguish between the two.

Therefore, these bioplastics may end up getting contaminated and may not be easily recyclable anymore. The outcome is adding up to the waste volume.

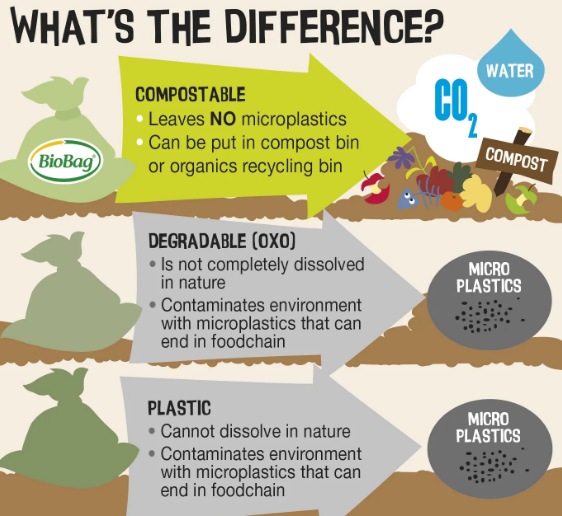

Some biodegradable plastics produce methane when decomposing in landfills. The amount of methane produced each year is high. Methane is 84 times more potent than carbon dioxide, and it absorbs heat faster; therefore, it can accelerate climate change.

These types of plastics cannot decompose in the ocean waters as it is too cold. Therefore, these plastics will either float on water or create micro-plastics which pose health hazards to marine life. Thus, the use of these kinds of plastic cannot solve all pollution problems.

Adequate production of these kinds of plastic will require the use of cropland to provide the natural materials required instead of producing food. With food scarcity and hunger affecting 1 out of 5 families in the developed nations and much more in developing countries, there is an ethical question whether it is right to expand this industry.

It costs 20 – 50% more to produce bioplastic than to produce traditional plastic. With improved technologies and more access to materials, however, this cost can reduce significantly.

Some of these plastic products, for example, plastic bags, may release some amount of heavy metals during decomposition. For example, the Guardian reported high levels of cobalt and lead in one brand of this kind of plastic. It raised issues about the toxicity left after decomposition.

It is a fact that biodegradable plastics can decompose really easily and even in a shorter timeframe. Still, it is also true that a very specific disposal method has to be followed with them. Failing this would mean that the decomposition process will be hampered.

Dumping them directly into the landfills would mean an unnecessary release of methane. Thus, it is essential to ensure that they are recycled, and we should also remember to use other waste reduction initiatives.

Corn-starch being one of the major components in the biodegradable plastic products, there must be water to ensure proper and timely decomposition of the biodegradable plastics. It means rain could facilitate its decomposition. But what if there is no rain? It could develop into a major problem managing these wastes at such times.

Biodegradable plastics do not track your exposure to herbicides and pesticides. There is no way to know if the crops that have been sent in for the manufacturing of these plastics were exposed to any such harmful chemicals. Thus, we still run a risk of being exposed to them.

|

They do not decompose unless they are disposed of properly, meaning that biodegradable plastics must be treated in special conditions. The natural breakdown of the plastic won’t occur if it is thrown in a landfill with other waste. Biodegradable plastics are more expensive because most of them have a higher density that contributes to the higher price. “Biodegradable” does not mean a material is compostable or recyclable. Biodegradable plastics may be manufactured from non-renewable resources. |

Uses of Biodegradable Plastics

Biodegradable plastics are used in many areas of our daily lives today. Some of these uses are;

To sum up,

Biodegradable plastics decompose naturally in the environment IF they are disposed of properly.

This is done when microorganisms in the environment break down the structure of biodegradable plastic.

Considering this, biodegradable plastic bags might be a better option, from the traditional plastic bags.

However, that doesn’t mean that they are a good everyday item. We need to use single-use products with caution and ONLY when it is absolutely necessary, and we have no other option.

They may have a few positive features, which separate them from the standard plastic bags. But that doesn’t make them that much better for the environment.

They can be harmful to the environment, if not taken proper care of after disposal.

Biodegradable plastics will only degrade by microorganisms if they are thrown away in the required environment for a proper breakdown.

Furthermore, biodegradable plastic can be less harmful, if it is obtained:

What is the future of biodegradable plastics?

Today, the main industrial applications for biodegradable and compostable plastics are bags distributed in supermarkets (38% of total consumption), the packaging sector (food cups and containers, films, nets, foams), and plastic bags for collecting and composting natural waste.

These applications are broadening, and in June 2020, the Citizen’s Convention suggested promoting “compostable biosourced packaging” to reduce plastic pollution.

Biodegradable polymers can go beyond food packaging and revolutionize furniture, batteries, toothbrushes, diapers, phones, computers, and more. Researchers continue to make progress in developing biodegradable materials that adhere to industry and safety guidelines and are affordable, renewable, and can compete with conventional plastics in terms of performance and durability while being eco-friendly. The world can look forward to biodegradable polymers bringing a big change to how every product is made.

Compostability is now seen as a positive and necessary alternative to plastic products that are still hard to replace: for example, composting could help overcome the difficulty in collecting and processing agricultural film. Biodegradable films can be left in the field after use then incorporated into the soil when it is prepared for the following crops. Compostable plastics will also reduce the volume of daily packaging waste by providing a real alternative for rethinking end-of-life plastics that cannot currently be recycled or reused because they are too thin, soiled, or multi-layered.

© 2025 iasgyan. All right reserved