Disclaimer: Copyright infringement not intended.

Introduction

Landfills have become a common feature of the landscape in many Indian cities. Increasing population, urbanisation and industrialisation are some of the main reasons for increased waste generation. A 2018 World Bank report also underlined the connection between economic development and waste generation.

The increasing industrialization, urbanization and changes in the pattern of life, which accompany the process of economic growth, give rise to generation of increasing quantities of wastes leading to increased threats to the environment.

During the budget session in 2022, Ministry of Environment, Forest and Climate Change informed that the total quantity of solid waste generated in the country was 1,50,761 tonnes per day in 2019-’20. The same World Bank report from 2018 states that India’s per capita waste generation lies at 0.57 kg per day as compared to 0.52 kg in South Asia and 0.74 kg at the global level. India, however, is yet to find a sustainable way to deal with this burgeoning waste in every city.

In recent years, technologies have been developed that not only help in generating substantial quantity of decentralized energy but also in reducing the quantity of waste for its safe disposal.

The Government is promoting all the technology options available for setting up projects for recovery of energy in the form of Biogas/BioCNG/Electricity from agricultural, Industrial and urban wastes of renewable nature such as municipal solid wastes, vegetable and other market wastes, slaughterhouse waste, agricultural residues and industrial/STP wastes & effluents.

To deal with challenges, state governments are also relying on waste-to-energy plants. The Ministry of New and Renewable Energy’s website says that the total estimated energy generation potential from urban and industrial organic waste in India is approximately 5,690 megawatts. But our capacity to manage waste has not grown with the pace of our capacity to generate waste. There is a huge gap between the quantity and quality of waste we are generating, and the capacity of the municipality to manage that waste.

A report titled “To Burn or Not To Burn”, by the Centre for Science and Environment that was published in 2019, says that plants of a combined capacity of 382.7 megawatts are proposed in India. According to the report, the plants with a capacity of 69.2 megawatts are operational, the ones with a capacity of 84.3 megawatts are under construction and 66.35 megawatts plants are non-functional.

Types of Waste

There are different types of waste which are generated from our daily or industrial activities such as organic waste, e-waste, hazardous waste, inert waste etc. Organic waste refers to waste which degrades or broken down by microorganisms over time. All organic wastes are essentially carbon based compounds; though they may be diverse in nature and have different degradation rate. Organic waste has significant portion in overall waste generation in industrial/urban/ agricultural sector and therefore it can be used for energy generation.

The organic fraction of waste can be further classified as non-biodegradable and biodegradable organic waste

Biodegradable waste consists of organics that can be utilized for food by naturally occurring micro- organisms within a reasonable length of time. The biodegradable organic comprise of agro residue, food processing rejections, municipal solid waste (food waste, leaves from garden waste, paper, cloths/ rags etc.), waste from poultry farms, cattle farm slaughter houses, dairy, sugar, distillery, paper, oil extraction plant, starch processing and leather industries.

Non-Biodegradable organic materials are organics resistant to biological degradation or have a very low degradation rate. This primarily includes woody plants, Cardboard, cartons, containers, wrappings, pouches, discarded clothing, wooden furniture, agricultural dry waste, bagasse, rice husk etc.

Waste-to-Energy (WtE)

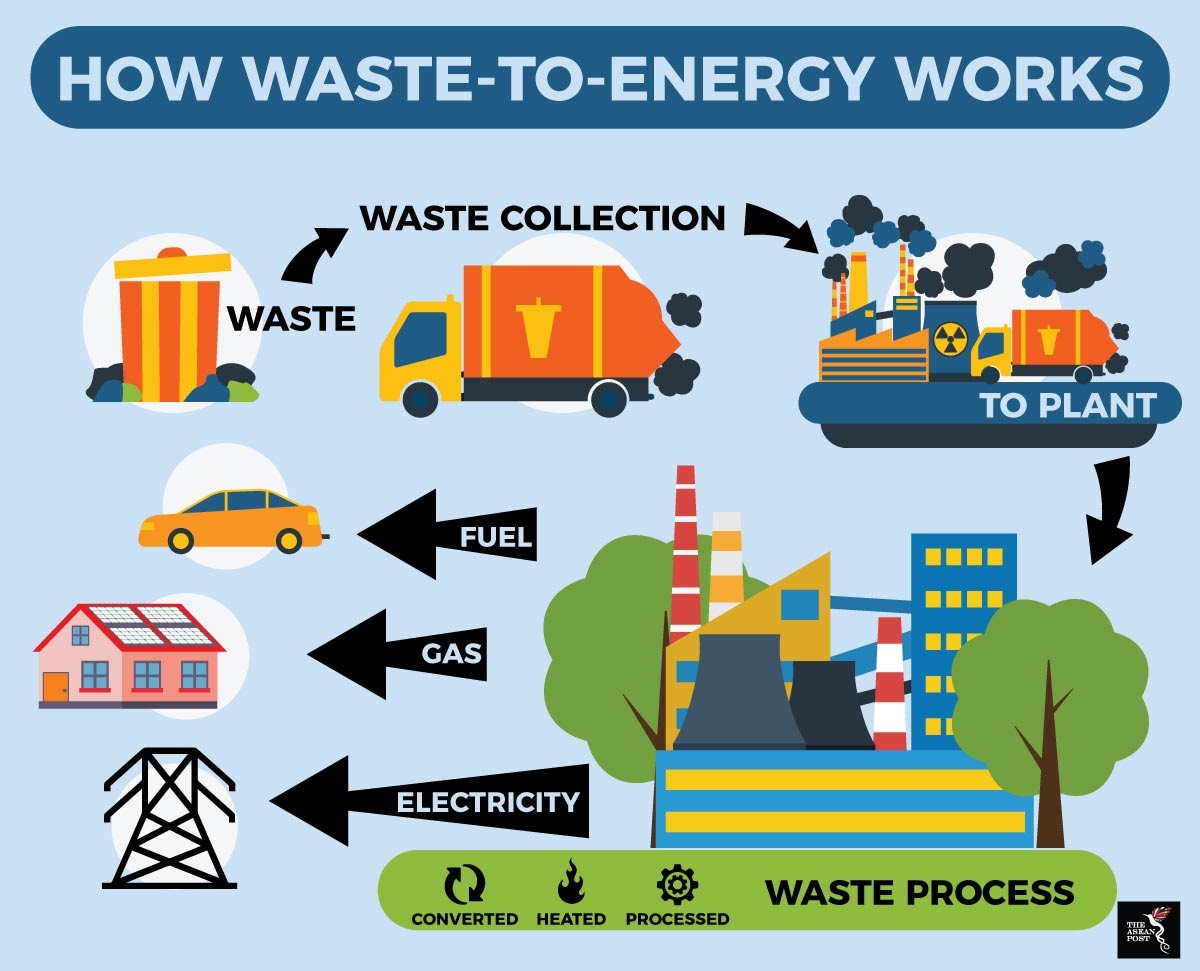

Waste-to-energy (WtE) or energy-from-waste (EfW) is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. WtE is a form of energy recovery.

Technologies available

Waste-to-Energy (WTE) technologies to recover the energy from the waste in the form of Electricity and Biogas/Syngas are given as below:

BIOMETHANATION

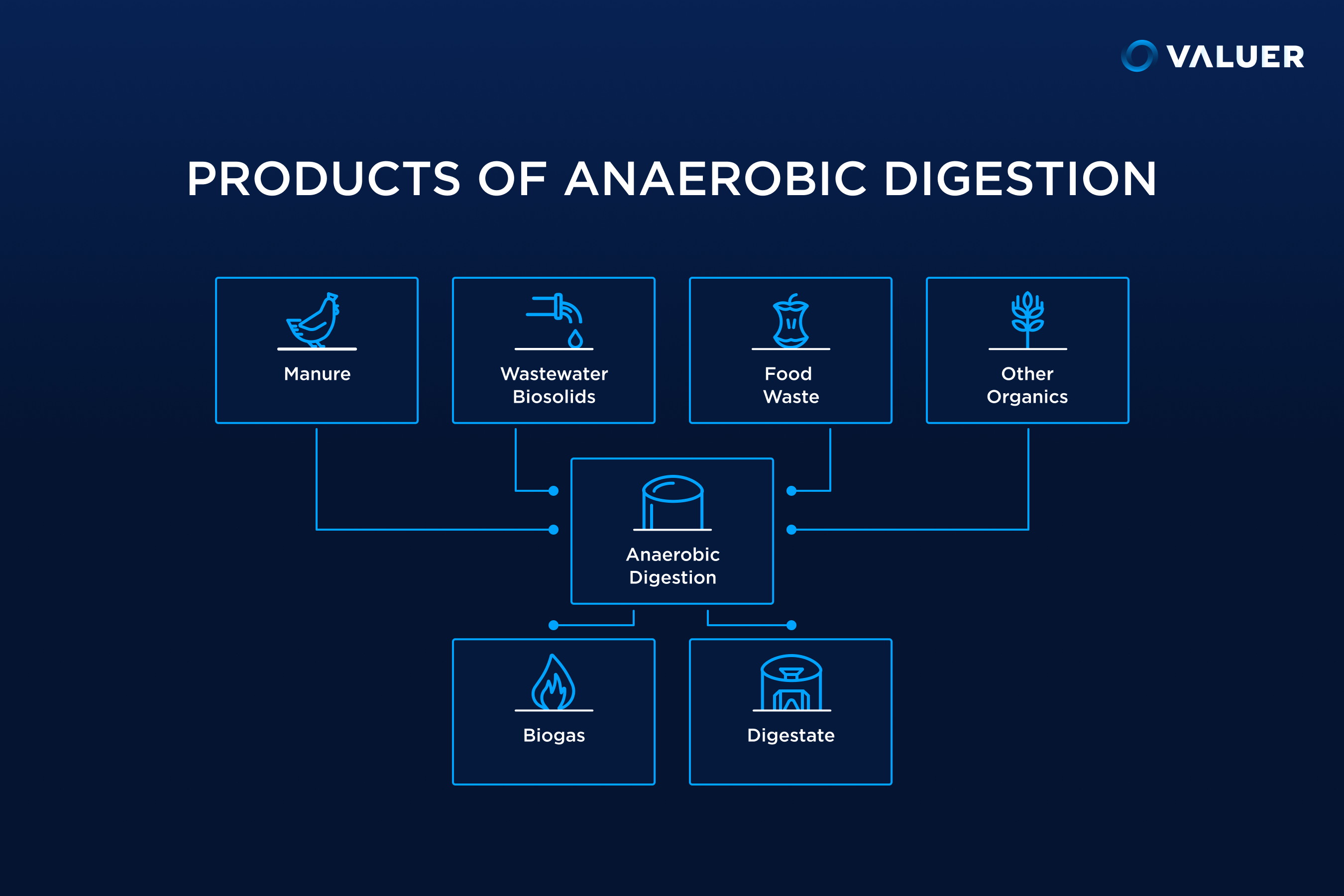

Biomethanation is anaerobic digestion of organic materials which is converted into biogas. Anaerobic digestion (AD) is a bacterial fermentation process that operates without free oxygen and results in a biogas containing mostly methane (~60%), carbon dioxide (~40%) and other gases. Biomethanation has dual benefits. It gives biogas as well as manure as end product.

This technology can be conveniently employed in a decentralized manner for biodegradation of segregated organic wet wastes such as wastes from kitchens, canteens, institutions, hotels, and slaughter houses and vegetables markets.

The biogas generated from Biomethanation process can be burned directly in a gas boiler/burner to produce heat for thermal application industries and cooking or burnt in a gas engine to produce electricity. Alternatively, the biogas can be cleaned to remove the carbon dioxide and other substances, to produce BioCNG. This can be injected into the national gas grid to be used in the same way as natural gas, or used as a vehicle fuel.

By using Biomethanation process, 20-25kgs of Cattle dung can generate about 1m3 of biogas and further 1m3 of Biogas has potential to generate 2 units of electricity or 0.4kgs of BioCNG.

INCINERATION

Incineration technology is complete combustion of waste (Municipal Solid Waste or Refuse derived fuel) with the recovery of heat to produce steam that in turn produces power through steam turbines.

The flue gases produced in the boilers have to be treated by an elaborate air pollution control system. The resultant ash from incineration of solid waste can be used as construction material after necessary processing while the residue can be safely disposed of in a landfill.

This technology is well established technology and has been deployed in many projects successfully at commercial level in India to treat solid wastes like Municipal Solid Waste and Industrial solid Waste etc. and generate electricity.

GASIFICATION

Gasification is a process that uses high temperatures (500-1800o C) in the presence of limited amounts of oxygen to decompose materials to produce synthetic gas (a mixture of carbon monoxide (CO) and hydrogen (H2)). Biomass, agro-residues, Segregated MSW and RDF pellets are used in the gasifier to produce Syngas. This gas further can be used for thermal or power generation purposes

The purpose of gasification of waste is to generate power more efficiently at lower power level (< 2MW) and also to minimize emissions and hence it is an attractive alternative for the thermal treatment of solid waste.

PYROLYSIS

Pyrolysis uses heat to break down combustible materials in the absence of oxygen, producing a mixture of combustible gases (primarily methane, complex hydrocarbons, hydrogen, and carbon monoxide), liquids and solid residues. The products of pyrolysis process are: (i) a gas mixture; (ii) a liquid (bio-oil/tar); (iii) a solid residue (carbon black). The gas generated by either of these processes can be used in boilers to provide heat, or it can be cleaned up and used in combustion turbine generators. The purpose of pyrolysis of waste is to minimize emissions and to maximize the gain.

Waste-to-energy pros and cons

As with any waste management process, there are pros and cons to WtE. Below are some of the main waste-to-energy advantages and disadvantages:

Waste-to-energy pros

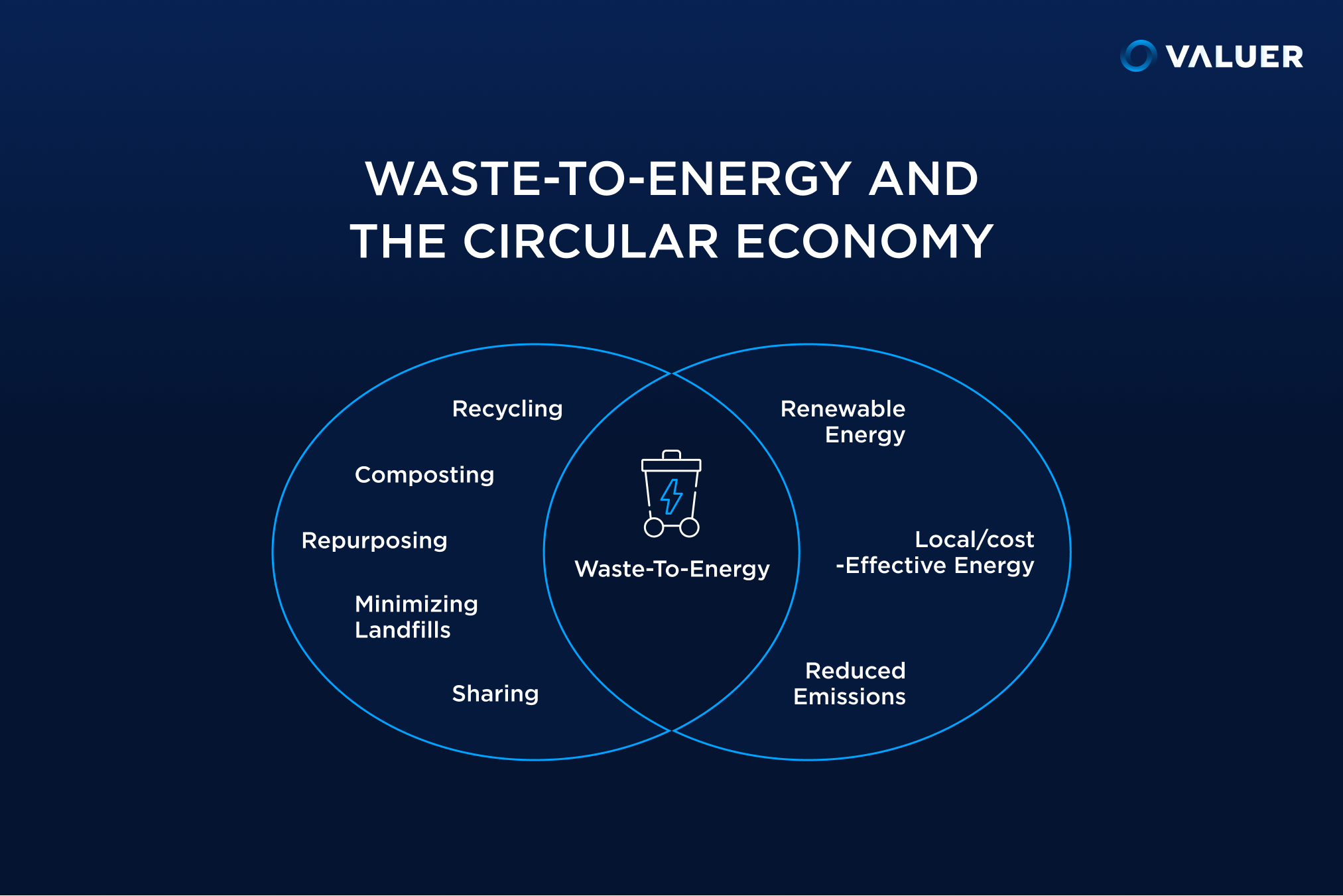

Waste-to-energy is used for a reason and compared to traditional waste management methods it certainly has some benefits, including the use of an otherwise wasted resource, a reduction in landfilling, and the opportunity for resource recovery.

Waste-to-energy is better than traditional incineration

Waste-to-energy is often promoted as “clean energy” when compared to wasteful incineration practices of the previous decades. In this regard, it is utilizing energy that would otherwise be wasted, while not technically increasing the amount of waste burned. That said, this argument only holds if incineration is the only option, whereas most responsible waste management plans are now looking toward less damaging, more circular solutions that contribute less to climate change.

Avoid landfilling

Landfills are the last resort when it comes to waste management, causing numerous issues such as the production of greenhouse gases, the usage of large pieces of land, the potential for pollutants to seep into the ground and groundwater, and more. Unfortunately, according to the Environmental Protection Agency figures from 2018, around 146 million tons of Municipal Solid Waste – that’s around 50% of all MSW – was sent to landfill.

Waste-to-energy processes at specialist incineration plants can greatly reduce the volume of waste that is landfilled. According to the US Energy Information Administration, WtE plants are able to reduce the volume of waste by about 87%, burning 2,000 pounds of garbage to ash weighing between 300 and 600 pounds. That said, this benefit is still based on the assumption that such large quantities of waste will continue to be produced—or continue to be allowed to be produced.

Resource recovery

Another benefit of waste-to-energy over landfilling is the opportunity to recover valuable resources such as metals post-incineration. They can then be sent for recycling and kept in the economy. This is even true of mixed materials, which are notoriously hard to recycle. Incineration burns away materials such as plastics leaving the metals behind, which can be considered better than landfills where recyclable materials are simply buried.

Waste-to-energy cons

The disadvantages of waste-to-energy are numerous and have become more apparent in recent years. They include the pollution and particulates it generates, the destruction of useful materials, and the potential to disincentivize more sustainable waste management solutions and renewable energy sources.

High CO2 emissions

Almost all the carbon content in the waste that is burned for WtE is emitted as carbon dioxide, which is one of the most notable greenhouse gases. That said if the waste-fuel is biomass – i.e. of natural origins, such as food waste, paper and paper board, wood, natural cloths like cotton – then the CO2 it contains was originally drawn from the atmosphere. However, plastics and other oil-based products, which are also burned in WtE, are equivalent to any other fossil fuel and emit damaging greenhouse gas emissions.

Potential to destroy recoverable materials

While waste-to-energy gives the opportunity to recover some resources, such as metals, it tends to destroy far more. In the US, incineration for WtE is most commonly completed through a process called “mass-burn”, whereby MSW is burned wholesale rather than being separated. In turn, the WtE process can destroy resources that could otherwise have been recovered, including minerals, wood, plastics, and more. This is especially true if there is not a rigid separation process for municipal solid waste ahead of incineration.

WtE could disincentivize recycling

Another of the waste-to-energy cons is the potential for it to disincentivize recycling or other more sustainable waste management methods. If people, organizations, or governments believe that waste-to-energy is a viable sustainable energy source and waste management technique, they are less likely to engage with or invest in more impactful solutions, such as reduction, reuse, or recycling. This can already be seen with the classification of many WtE power plants as “renewable energy”.

It fuels an unregulated waste trade

Today, many developed countries send their waste to developing countries for processing, often as part of a broader waste management plan that claims to improve recycling rates. In some cases, waste is recycled, but often it is simply incinerated or used in waste-to-energy facilities. China’s National Sword Policy highlighted the scale of this practice.

Unfortunately, while Western countries will claim this practice as part of their recycling targets, the unregulated nature of this trade often means improper disposal, with WtE a major factor. In fact, it has even been shown that hazardous wastes not meant for incineration are commonly shipped abroad where they are burned before being landfilled.

Primitive methods: outweighs the benefits.

There are two traditional paths for un-diverted waste: landfill and incinerator. Neither is ideal, however, during the 19th century there was an attempt to improve the situation. Engineers in Europe saw an opportunity for energy recovery in a range of waste streams, and rather than simply burning trash to dispose of it, it was determined the heat from waste incineration could be used to power turbines—and so, waste-to-energy was born.

However, more than a hundred years later, those same primitive methods are still at the core of our waste disposal, and as people seek cleaner energy and more sustainable waste management, the problems of waste-to-energy have started to outweigh the benefits.

Not economically viable

Pollution coming from waste-to-energy plants is another issue and the poor quality of waste put into the plants is making them unviable. Most of these plants are established at competitive bidding, which means they have to provide energy at Rs 5 or Rs 7 per unit. If supplementary energy is needed, they are not economically viable and get closed down.

More than half of the waste-to-energy plants have shut down today, which says that technology improvements do not work with the quality of waste that is being generated today. To add a comparative perspective, solar and wind energy cost somewhere between Rs 2 and Rs 3 per unit while the tariff of thermal energy is in the range of Rs 4.5 to Rs 6.

Other waste-to-energy systems

Incineration is not the only waste-to-energy method, and there is an increasing number of techniques that are being implemented to make waste processing more sustainable. Some of the other notable WtE methods include:

Gasification

While as a process, gasification has been used for centuries, it has only been applied to waste in a serious way in the past few decades. It works by processing biomass at extremely high temperatures without combustion, which produces combustible natural gas – also called syngas. This gas is then used as a fuel source.

Fermentation and distillation

Biomass can be fermented and distilled to create ethanol. This can then be used as an alternative fuel for engines or other applications. As with other WtE methods, this can only be used for organic waste and other similar waste streams.

Anaerobic digestion

This is a process in which microorganisms break down biomass in an oxygen-free environment. It produces biogas high in methane which can then be used as a fuel source to produce electricity and other applications.

Plasma gasification

Plasma gasification utilizes a plasma torch at extremely high temperatures (generally between 5,000 and 7,000 °C, but can be higher or lower) in a single reactor to turn feedstock (biomass, coal, municipal waste, etc.) into that very same syngas (mainly made up of hydrogen and carbon monoxide) we just talked about. This breakdown of molecules and change of chemical composition due to plasma torching is also referred to as plasma pyrolysis.

Not only is the resulting syngas used as fuel and cleaned prior to use, but plasma gasification also creates valuable by-products. The glass-like byproduct of the process, i.e. the slag that remains from the melted waste of plasma falsification, is safe to use as a construction material. If you’re worried about toxins, don’t! Plasma torches have been utilized to destroy toxic waste and chemical weapons in the past.

The downside here is that dioxins still get released as the syngas cools down. Still, they’re significantly less in comparison to the dioxins (and furans) that are formed at traditional incinerator plants.

Hydrothermal carbonization (HTC)

Hydrothermal Carbonization (HTC) is a thermochemical process that turns organic waste into structured carbons similar to fossil fuels (that take up to millions of years to form naturally). HTC works with wet feedstock, and the process combines an acid catalyst and pressure at somewhat high temperatures (180 to 250°C) to produce hydro-char, this fossil fuel-like product that has high levels of carbon.

Not only can hydro-char be used as fuel but it can also be used to replace coal. The product can also be used to enrich soil, while the feedstock can be used for gasification.

The main advantage of HTC over other thermochemical technologies like pyrolysis is that it doesn’t require pre-treatment (pre-drying) of the feedstock, as it’s designed to work with wet waste, which makes the process a lot faster.

It also requires similar operating conditions to anaerobic digestion for the same energy output. This, combined with the faster processing time, gives HTC an edge over competitive WtE methods like anaerobic digestion.

Dendro liquid energy (DLE)

Dendro liquid energy (DLE) is probably the most promising and up-and-coming near-zero emissions waste-to-energy technology that treats waste biologically. DLE plants operate at moderate temperatures between 150°C and 250°C, which makes them about four times more efficient in generating electricity when compared to anaerobic digestion and other WtE solutions.

Dendro liquid energy plants work with both wet and dry waste to generate clean fuels for electricity like hydrogen and carbon monoxide - basically, it produces syngas. What’s more, DLE is cost-efficient because the process doesn’t contain combustion, meaning it doesn’t need expensive anti-emission technology to be environmentally safe.

Some of the main advantages of DLE are that it has a high energy conversion of around 80% efficiency, and near-zero emissions, meaning the byproduct and syngas don’t contain particulates and tar. Furthermore, it works with mixed waste (dry and wet) to produce clean fuel and its low operating cost makes it a perfect local solution for various municipalities.

Recycling

Recycling is perhaps the most obvious alternative to disposing waste in landfills. An increasing range of products—such as paper, plastic, textiles, wood, aluminum, and glass—can be recycled through various processes. By recycling such products, one can convert materials that would have otherwise been thrown in a landfill into reusable materials.

Composting

Composting is a well-recognized alternative to disposing waste in landfills. This environmentally-friendly process allows biological waste to naturally decompose into fertilizer for plants, due to the presence of microorganisms and oxygen. Composting is such a simple process that many people can do it right in their backyards to reduce household waste. There are companies like ewmdumpsterrental.com that not only focus on waste disposal but also offer compost picks up from customers and deliver them to compost sites at a very low cost.

Future of waste-to-energy

Unfortunately, there is no silver bullet when it comes to lowering carbon emissions and dealing with our waste products. As is often the case, a balanced approach is needed.

Solutions like WtE are best viewed on a spectrum. Most green energy and waste disposal methods still have some detrimental effects on the environment. When we evaluate methods like waste incineration, it is often a question of weighing up the pros and cons and seeing it as part of, not the whole solution.

It is important for the environmental and scientific communities to continue to explore fossil fuel alternatives and promote Zero Waste paths as we move forward in our battle against climate change.

WtE is not without its negatives, but it is better than landfill – and for many countries under pressure to act on climate change.

So, despite some of the drawbacks of waste-to-energy technologies, they appear to be a crucial step in dealing with the negative effects of growing landfills - as long as only non-recyclable, non-repurposable materials are fed into WtE machines and the necessary measures are taken to minimize air pollutants.

On an even brighter note, the growing need for better WtE technologies has led to developments like DLE, processes that have near-zero emissions, are cost-efficient and energy-efficient.

Innovation here is what is driving the sustainable technologies of waste-to-energy forward. One way to stay ahead of the curve when it comes to disruptive technologies is to incorporate data-driven insights into an industry or sub-sector.

Objectively, - zero-waste is the most sustainable way forward.

© 2025 iasgyan. All right reserved