Description

Copyright infringement is not intended

Context: India & Denmark agreed to initiate joint research and development on green fuels including green hydrogen, during the Joint S&T Committee meeting.

Key highlights of the Joint Committee:

- It emphasized on development of bilateral collaboration on mission-driven research, innovation, and technology development, including climate and green transition, energy, water, waste, food and so on.

- Green Strategic Partnership – Action Plan 2020-2025

About Hydrogen

- There are no natural hydrogen deposits on earth, it has to be extracted from other compounds by a chemical process.

- The vast majority of industrial hydrogen is currently produced from natural gas through a process known as steam methane reforming or SMR.

- Producing hydrogen in this way is sometimes referred to as brown or grey or even blue hydrogen.

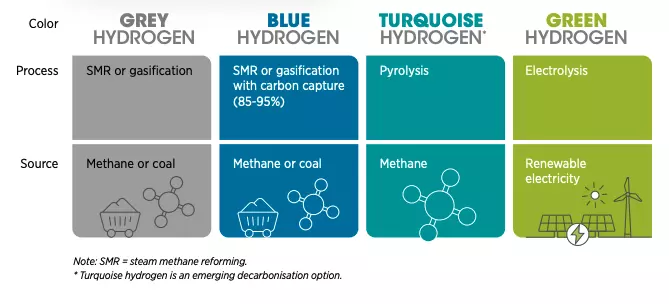

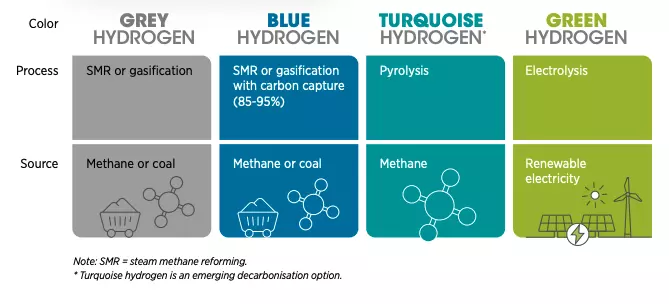

Types of Hydrogen:

- Brown Hydrogen: most of the gas that is already widely used as an industrial chemical is either brown, if it's made through the gasification of coal or lignite

- Grey Hydrogen: if it is made through steam methane reformation, which typically uses natural gas as the feedstock. Neither of these processes is exactly carbon-friendly.

- Blue Hydorgen: where the gas is produced by steam methane reformation but the emissions are curtailed using carbon capture and storage.

- Green Hydrogen: Green hydrogen, in contrast, could almost eliminate emissions by using renewable energy — increasingly abundant and often generated at less-than-ideal times — to power the electrolysis of water.

Green hydrogen current status

- At present, less than 1 per cent of hydrogen produced is green hydrogen, according to IRENA's World Energy Transitions Outlook.

- India consumes about six million tonnes of hydrogen every year. This could increase to 28 million tonnes by 2050.

- India has favorable geographic location and abundance of sunlight and wind for the production of green hydrogen.

- India will become a net exporter of green hydrogen by 2030 due to its cheap renewable energy tariffs, according to the Global Hydrogen Council.

Challenge in making Green Hydrogen:

- Storing and transportation: H2 is a highly flammable gas, it takes up a lot of space and has a habit of making steel pipes and welds brittle and prone to failure.

- High Cost: The International Energy Agency put the cost of green hydrogen at $3 to $7.50 per kilo, compared to $0.90 to $3.20 for production using steam methane reformation.

- Loss of Efficiency in every process: Electrolyzer efficiencies range from around 60 percent to 80 percent.

Significance

- Achieve targets pledged under the Paris Climate Agreement i.e. to reduce the emission intensity of its economy by 33-35 per cent from 2005 levels by 2030.

- Provide an alternative to fossil fuels

- Provide a transition toward low emissions and work towards a clean, healthy environment.

Why India should opt for Green Hydrogen?

- Adoption of Green hydrogen technologies are favorable in those sectors where direct electrification isn't feasiblefor ex in Heavy duty, long-range transport and long-term storage in the power sector.

- With technological improvements, green hydrogen will become more affordable and accessible.

- It can be used in a wide range of existing applications such as fertilisers, mobility, power, chemicals and shipping.

- It can be blended up to 10 per cent by city gas distribution networks for wider acceptance.

- It is a cross-cutting solution that may reduce emissions across a range of sectors.

What can India do to build a global-scale green hydrogen industry?

- India should announce ambitious national targets for green hydrogenand electrolyser capacity by 2030.

- Launch an incentive programme for the production of electrolysers.

- Implementing complementary solutionsthat create virtuous cycles for ex. building the hydrogen infrastructure for refueling, heating and generating electricity at airports.

- Optimising distribution networksto decarbonise the gas grid.

https://www.pib.gov.in/PressReleasePage.aspx?PRID=1790951