Description

Figure 3: No Copyright Infringement Intended

Context:

- The government is planning to blend 15 per cent green hydrogen with piped natural gas (PNG) for domestic, commercial and industrial consumption.

About

- The move is in line with India’s ambitious target of reducing greenhouse emissions and becoming carbon neutral by 2070.

- This initiative will be part of the government’s National Hydrogen Energy Mission aimed at generating hydrogen from green power sources.

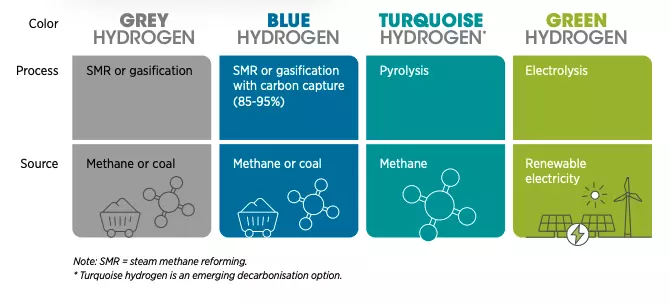

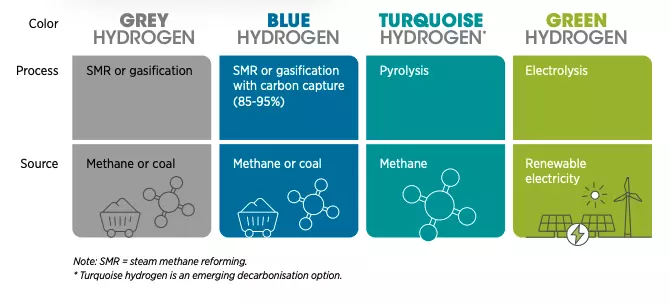

Types of Hydrogen:

- Brown Hydrogen:most of the gas that is already widely used as an industrial chemical is either brown, if it's made through the gasification of coal or lignite

- Grey Hydrogen:if it is made through steam methane reformation, which typically uses natural gas as the feedstock. Neither of these processes is exactly carbon-friendly.

- Blue Hydorgen: where the gas is produced by steam methane reformation but the emissions are curtailed using carbon capture and storage.

- Green Hydrogen: Green hydrogen, in contrast, could almost eliminate emissions by using renewable energy — increasingly abundant and often generated at less-than-ideal times — to power the electrolysis of water.

Making of Green Hydrogen:

- With electrolysis, all you need to produce large amounts of hydrogen is water, a big electrolyzer and plentiful supplies of electricity.

Usage of it:

- replace the industrial hydrogen that gets made every year from natural gas

- use it as a precursor for other energy carriers, from ammonia to synthetic hydrocarbons

- directly power fuel cells in cars and ships

- add it to natural gas and burn it in thermal power or district heating plants.

Challenge in making it:

- The challenge right now is that big electrolyzers are in short supply, and plentiful supplies of renewable electricity still come at a significant

- Storing and transporting the highly flammable gas is not easy; it takes up a lot of space and has a habit of making steel pipes and welds brittle and prone to failure.

- The bulk transport of hydrogen will require dedicated pipelines, which would be costly to build, pressurizing the gas, or cooling it to a liquid.

- High Cost:In a report published last year (using data from 2018), the International Energy Agency put the cost of green hydrogen at $3 to $7.50 per kilo, compared to $0.90 to $3.20 for production using steam methane reformation.

- Loss of Efficiency in every process:Electrolyzer efficiencies range from around 60 percent to 80 percent, according to Shell. The efficiency challenge is exacerbated by the fact that many applications may require green hydrogen to power a fuel cell, leading to further losses.

Why Green Hydrogren is such a big deal:

- Green hydrogen is one of several potential low-carbon fuels that could take the place of today’s fossil hydrocarbons.

- other low-carbon fuels require the production of green hydrogen as a precursor, why not just stick with the original product?

- hydrogen is already widely used by industry, so technical problems relating to storage and transport are not likely to be insurmountable.

- the gas is potentially very versatile, with possible applications in areas rangingfrom heating and long-term energy storage to transportation.

- The opportunity for green hydrogen to be applied across a wide range of sectors means there is a correspondingly large number of companies that could benefit from a burgeoning hydrogen fuel economy.

Current Production:

- Green hydrogen currently accounts for less than 1 percent oftotal annual hydrogen production.

- The pipeline of green hydrogen electrolyzer projects nearlytripled in the five months leading up to April 2020, to 8.2 gigawatts.

Green Hydrogen Infrastructure in India:

- Government has said that country was focusing on producing blue and green hydrogen along with blended hydrogen in Compressed Natural Gas (CNG) for various purposes, including transport.

- Through technological advancements, India is blending hydrogen with compressed natural gas foruse as transportation fuel as well as an industrial input to refineries.

- 50 buses in Delhi are plying on blended hydrogenin Compressed Natural Gas on a pilot basis.

- the Indian Oil Corporation Limited announcedit would set up the country’s first green hydrogen

- Reliance Energy said that it would invest Rs 600 billion in building factories to produce green hydrogen among other carbon friendly technologies.