Description

Disclaimer: Copyright infringement not intended.

Context

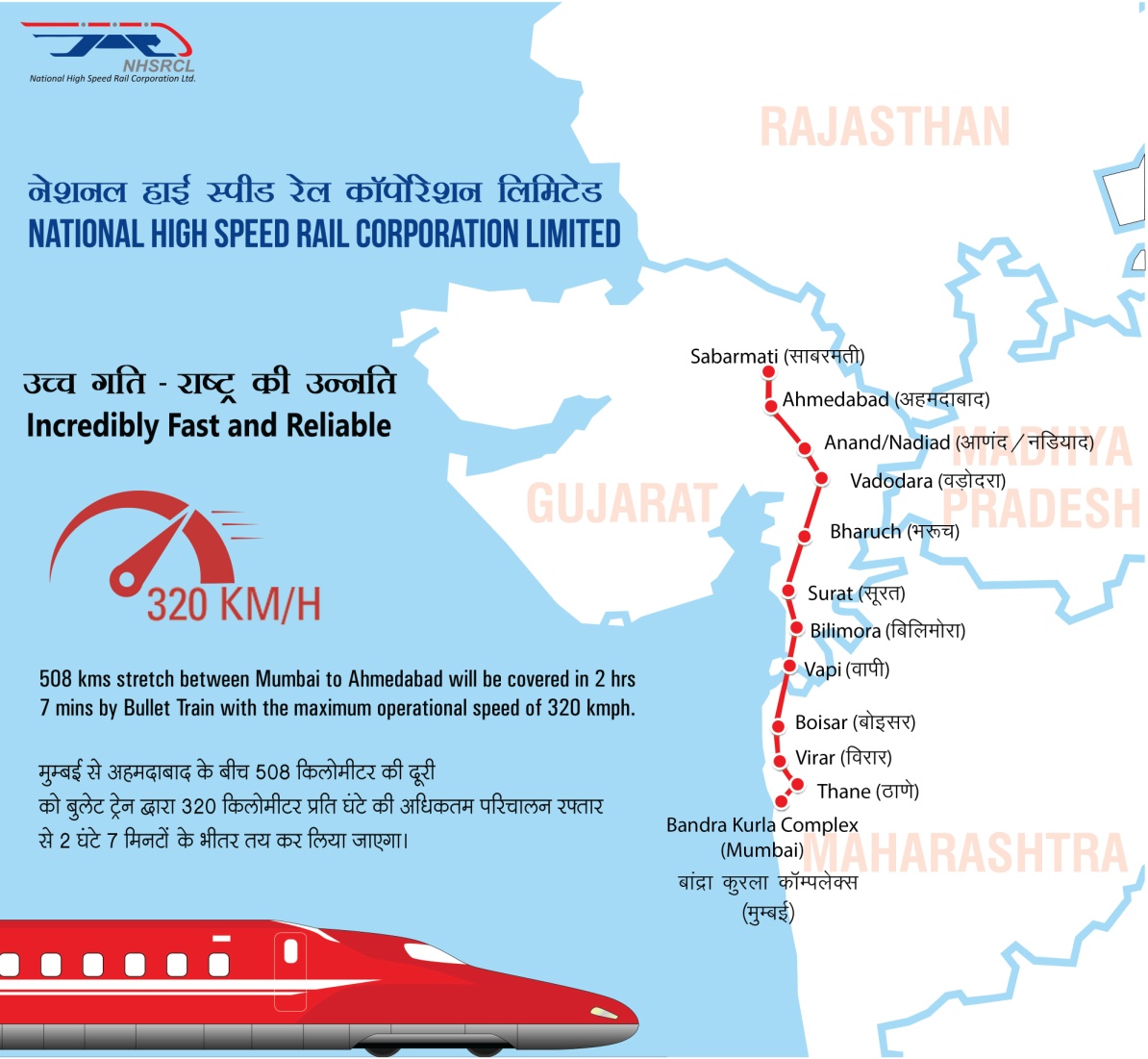

- The trials of Bullet Trains under Mumbai–Ahmedabad High Speed Rail Corridor will be conducted between Gujarat’s Bilimora and Surat in 2026.

- Officials of the National High Speed Rail Corporation Ltd (NHSRCL) and Japanese Ambassador to India are reviewing the progress of work on the project route.

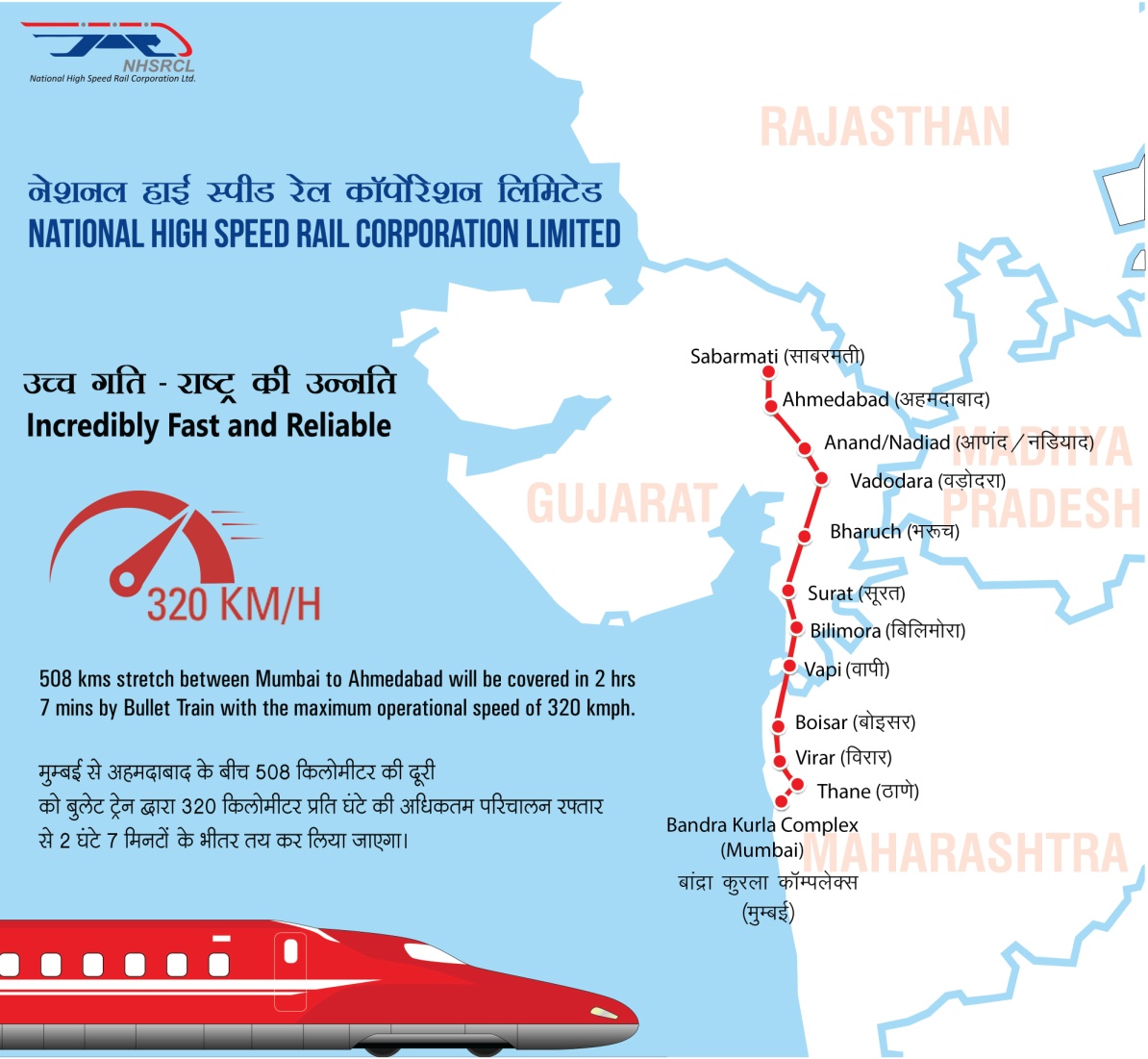

MAHSR Corridor

- Mumbai–Ahmedabad High Speed Rail Corridor (MAHSR corridor) is an under-construction high-speed rail line connecting India's economic hub Mumbai with the city of Ahmedabad.

- When completed, it will be India's first high-speed rail line. The stretch of 50 km from Surat to Bilimora is expected to be completed by 2026.

Details

- Speed: The train will run at a speed of 350km per hour and the operational speed of the train will be 320kmph.

- Length of Corridor: The total length of the bullet train corridor is 508.17 km and the train is expected to take around 2 hours and 58 minutes to travel between Ahmadabad and Mumbai, covering eight stations in Gujarat and four in Maharashtra.

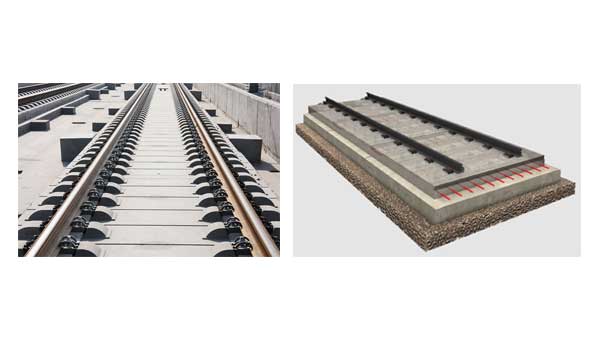

- Tracks and Construction Technology: The trains will run on special tracks called the “slab track system”, popularly known as HSR technology for construction of tracks, patented by Japanese. Using designs procured from Japan, construction is being done through the Full Span Launching Method, one of the sophisticated bridge construction technologies in the world.

- Compared to Aeroplanes: The services will come at a fare matching the economy-class flights and are likely to have a higher free-luggage limit. The bullet train will have less check-in time, more leg space and above all, connectivity, which is denied on-board airplanes.

- Funding: The Japanese government funded more than 80 per cent of the project at an interest rate of 0.1 per cent and has given India 50 years to repay.

Track Technology (Ballasted Vs Non Ballasted)

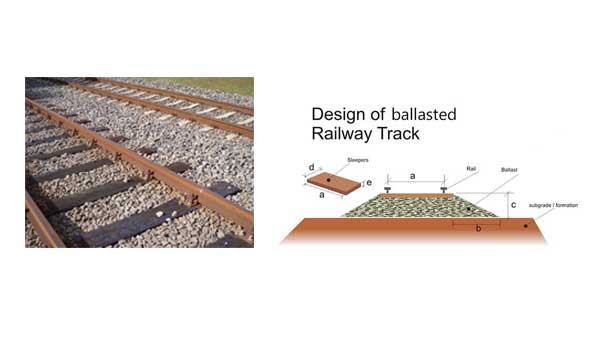

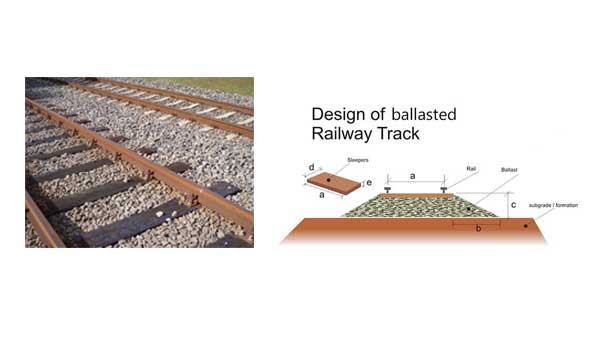

Traditional ballasted track

- Ballasted track is commonly composed of steel rail, railroad tie, railway fasteners and ballast bed.

- On traditional ballasted track, the rail is mounted onto a wooden or concrete sleeper.

- A layer of gravel is laid between ground and railway sleeper to form the track bed. Track bed (ballast bed) can improve the flexibility and drainage performance of railway track.

- Traditional ballasted track has been used since the earliest days of the Victorian railways and has changed little in concept since that time.

Advantages:

- Ballasted track requires low investment cost.

- Ballasted track is usually easy to lay.

- Ballasted track has good drainage performance.

Disadvantages:

- Train run on the ballasted track with banged sound and low speed. so that, passengers may feel uncomfortable.

- Ballasted track is easy to be deformed.

- Ballasted bed requires frequent and costly maintenance.

- Train speed is limited on the ballasted track.

- Ballasted track has poor life expectation (about 15-20yrs).

- Ballasted track produce more pollution by releasing dust from ballast.

- Ballasted track has higher noise level than non-ballasted track. It is necessary to take effective noise reduction measures.

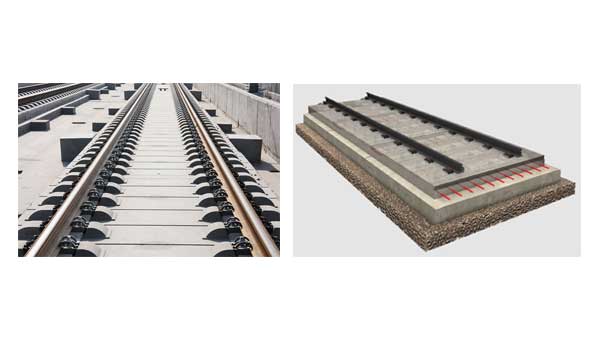

Non-Ballasted Track

- Non-ballasted track, also called ballastless track, is the railway track whose bed is composed of concrete and bituminous mixture, etc. Generally, non-ballasted track is made up of steel rail, railway fasteners and slab.

- Non-ballasted track’s railway sleeper is formed by concrete casting. Instead of ballast bed, steel rail and railway sleeper is laid on the concrete track.

- With concrete track slab systems, the ballast is replaced by a rigid concrete track slab which transfers the load and provides track stability.

- Resilience is introduced into the track system by means of elastomeric components. These may be pads, bearings or springs depending on the type of slab track system.

- Non-ballasted track is the advanced track technology in the world.

|

Concrete Slab Track Technology (A type of Non-Ballasted Track)

Slab track is one of the most important types of non-ballast track structure.

Slab Track structure also called ballastless track, is a unique feature of Japanese High Speed Railway, popularly known as Shinkansen. The first HSR in Japan i.e. Tokaido Shinkansen began operational in 1964 between Tokyo and Shin-Osaka.

|

Advantages:

- Non-ballasted track need less maintenance, save cost.

- Non-ballasted track can reduce dust and beautify the environment.

- Non-ballasted track has great ride performance and stability.

- Non-ballasted track has long durability and service life (about 50-60yrs).

- Non-ballasted track has high train speed and make passengers feel comfortable.

Disadvantages:

- Non-ballasted need more investment cost than ballasted track.

- Non-ballasted track cannot be laid in some area like clay deep cutting, soft dirt road and earthquake area.

- Possibilities for improvement are limited.

About National High Speed Rail Corporation Limited

- National High-Speed Rail Corporation Limited (NHSRCL) was incorporated in 2016 under the Companies Act, 2013.

- Its objective is to finance, construct, maintain and manage the High Speed Rail Corridor in India.

- The Company has been modeled as ‘Special Purpose Vehicle’ in the joint sector with equity participation by Central Government through Ministry of Railways and two State Governments - Government of Gujarat and Government of Maharashtra.

- The Company would be ushering India into the category of few countries of the world (about 15) using High Speed Railway System.

Benefits of High-Speed Rail

- There are a number of social and economic benefits that comes with the introduction of High-Speed Rail. Most recent examples are from Japan, Europe and China where high-speed rail has done wonders for the common citizens by providing high speed connectivity between various towns and cities.

Social Benefits

- There are a number of positive externalities of high-speed rail like economic travel, reduced CO2 emission, comparatively less land required than a 6 lane highway for same passenger capacity and employment generation because of higher economic activity and faster connectivity.

Economic benefits

- Transportation by HSR would be powered by indigenous electric power unlike diesel/petrol and aviation fuel need by cars and airplanes, which is largely imported. This will benefit the Indian economy and reduce its relevance on imported fuel.

- According to a study conducted by London School of Economics and Political Science, towns connected to a new high-speed line saw their GDP rise by at least 2.7% compared to the neighbors not on the route.

- Their study also found that increased market access through high-speed rail has a direct correlation with a rise in GDP-for each 1% increase in market access, there is a 0.25% rise in GDP.

Final Thought

- The High-Speed Rail (HSR) project would afford many quantifiable benefits like saving in travel time, vehicle operation cost, reduction in pollution, job creation, reduction in accidents/ enhanced safety, imported fuel substitution, and reduction in pollutants. The project would also boost the infrastructure and add to the growth of economy.

https://indianexpress.com/article/india/bullet-train-trials-to-be-conducted-at-350-kmph-in-2026-say-officials-7868347/