Fire in electric vehicles

Disclaimer: Copyright infringement not intended.

Context

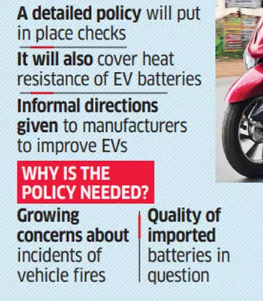

- Amid increasing instances of fires in electric vehicles (EVs) being reported from parts of the country, the government has stepped in with a plan to formulate procedures on battery certification and quality control.

Background

- The electric two-wheeler segment has seen many incidents of vehicles catching fire in the recent past. Electric two-wheeler makers such as Ola Electric, Okinawa Autotech and PureEV had recalled their scooters in the wake of separate fire incidents.

- The reasons for fire may include manufacturing defects, external damage, or faults in the deployment in the battery management system, which could result in these batteries becoming a fire risk. In some cases, faulty charging could also have been a reason behind the fire.

Steps being taken

- The Centre has formed a panel of experts that has representations from the Visakhapatnam-based Naval Science & Technological Laboratory; the Indian Institute of Technology, Madras; the Indian Institute of Science, Bengaluru; and an expert of advanced chemistry.

- “The committee will suggest ways to ensure the right quality of the product. They have to come up with a Standard Operating Procedure (SOP) for testing and validation of key components and formulate a certification standard for the battery used in EVs.

Components of Li-ion battery

- Every Li-ion battery consists of three active components: the anode, typically graphite; the cathode, typically based on a nickel, cobalt, and manganese-based oxide; and an electrolyte, typically a salt of lithium in an inorganic solvent. Battery manufacturing is a complex operation involving forming sheets of the anode and cathode and assembling them into a sandwich structure held apart by a thin separator.

Features of Lithium-ion batteries

- Lithium-ion batteries, which came into commercial use in the early 1990s, have a very high energy density and are less likely than most batteries to lose their charge when not being used -- a property called self discharge.

- Because of their light weight and low maintenance requirements, lithium-ion batteries are widely used in electronic devices such as laptop computers.

- Some experts believe that lithium-ion batteries are about as close as science has yet come to developing a perfect rechargeable battery, and this type of battery is the best candidate for powering the electric cars. These batteries are also used in most portable electronics, including cell phones and computers.

- Lithium-ion batteries have a high power-to-weight ratio, high energy efficiency and good high-temperature performance.

- In practice, this means that the batteries hold a lot of energy for their weight, which is vital for electric cars – less weight means the car can travel further on a single charge.

- Lithium-ion batteries also have a low “self-discharge” rate, which means that they are better than other batteries at maintaining the ability to hold a full charge over time.

- Additionally, most lithium-ion battery parts are recyclable making these batteries a good choice for the environmentally conscious.

- The major advantage of lead-acid batteries is that, they are cheap to produce. However, they do produce dangerous gases while being used and if the battery is overcharged there's a risk of explosion.

|

A variation on lithium-ion batteries, called lithium-ion polymer batteries, may also prove valuable to the future of EVs. These batteries may eventually cost less to build than lithium-ion batteries; however, at the present time, lithium-ion polymer batteries are prohibitively expensive. |

What causes battery fires?

- Battery fires, like other fires, occur due to the convergence of three parts of the “fire triangle”: heat, oxygen, and

- If an adverse event such as a short circuit occurs in the battery, the internal temperature can raise as the anode and cathode release their energy through the short.

- This, in turn, can lead to a series of reactions from the battery materials, especially the cathode, that release heat in an uncontrolled manner, along with oxygen.

- Such events also rupture the sealed battery further exposing the components to outside air and the second part of the fire triangle, namely, oxygen.

- The final component of the triangle is the liquid electrolyte, which is flammable and serves as a fuel. The combination leads to a catastrophic failure of the battery resulting in smoke, heat, and fire, released instantaneously and explosively.

- The trigger for such events can be a result of

- Internal shorts (like a manufacturing defect that results in sharp objects penetrating the separator),

- External events (an accident leading to puncture of the cell and shorting of the electrodes),

- Overcharging the battery which leads to heat releasing reactions on the cathode (by a faulty battery management system that does not shut down charging despite the battery achieving its designed charge state), or

- Bad thermal design at the module and pack level (by not allowing the battery internal heat to be released). Any of these triggers may cascade into a significant safety incident.

Preventing Fires

- Preventing fires requires breaking the fire triangle. Battery cathodes are a leading cause of the heat release. Some cathodes, such as ones with lower nickel content or moving to iron phosphate, can increase safety.

- Tightly controlled manufacturing will prevent accidental shorts in the cells, eliminating a leading cause of fires.

- Many companies now add a ceramic layer on the separator to mechanically prevent shorts.

- Sensing the state of the battery and integrating this data into sophisticated battery management systems is an important aspect of design.

- Protecting the cell with robust thermal management is critical, especially in India where ambient temperatures are high.

- Finally, battery packs need to be protected from external penetration. Any large-scale manufacturing process inevitably has a certain percentage of defects; therefore, such steps are needed to minimize the number of adverse events.

Way Ahead

- Companies are rightly developing internal “switches” that turn off parts of the battery that undergo thermal events to stop them at their inception. Research is now underway to replace the flammable liquid electrolyte with a solid electrolyte to eliminate one part of the fire triangle.

- A similar thread of research is the development of non-flammable liquid electrolytes. All these changes promise to remove the threat of battery fires as the roll out of mass electrification takes place.

- Engineering safety requires commitment from all parts of the battery supply chain and tight integration between vehicle companies and battery companies.

- Regulators play an important role, providing the testing and certification needed to ensure that technology innovations perform at the level that is promised.

- Only Companies with tightly controlled manufacturing with years of experience should be allowed to manufacture. needs to come out with standards for electric vehicle (EV) batteries. There is a need of norms to put in place quality controls for batteries used in EVs.

https://indianexpress.com/article/business/commodities/ev-fires-govt-sets-up-panel-to-suggest-certification-testing-sops-for-batteries-8013657/

1.png)